|

|

|

|

Organizing a Woodshop in One Saturday

By Steve Johnson

|

|

|

Early on a Saturday morning, distinctive telltale sounds that would perk up any woodworker’s ears were wafting down my street. First the short wind-up of an electric motor, then the sound of a blade cutting wood, then a short wind-down and silence. Seconds later, the exact sounds repeated… and then again. I’ve been woodworking long enough to not only know the sound, but to know the blade wasn’t sharp… and the brand of miter saw.

Where could that be coming from? I don’t know everyone in the neighborhood, but I should know any other woodworkers. Curiosity took over and I struck out, intent on finding the source of that sweet sawing sound. But the repetitive cutting stopped and there was no longer a beacon of sound to follow. Fortunately I spied an open garage door. That was the place.

The shop was a crowded corner in the back of the garage. Along the back wall were several tall plastic storage cabinets. The bases of several discarded kitchen cabinets took up about six feet on the adjacent wall. A piece of plywood over the top of those cabinets formed a work surface of sorts, and the miter saw was bolted down to the plywood. Next to the bench was a tall deep set of metal shelves, loaded to capacity. Next to that, piles of predictable garage “stuff,” including a lawnmower, two bicycles, a weed whacker, and more, lined the remaining length of the wall.

While we talked, my new acquaintance was struggling to figure out how to cut six feet from several eight-foot long boards. I don’t have a degree in physics or differential calculus, but it was evident there was no way… at least with the current arrangement. An eight-foot board simply would not fit between the corner and the shelves.

There were really only a few viable options. Move the shelves at one end of the bench so the long boards would fit (likely a Herculean task), unbolt the miter saw and move it somewhere more spacious, or cut the boards somewhere else, using a different tool.

While we talked I watched my neighbor rummage through cabinet after cabinet until he found his jigsaw. I held the boards at an angle on his bench, and he cut the ends off. Not perfect cuts, but passable for what he was building.

He told me he loves to work with wood, but doesn’t much. “I just don’t have the space,” he explained. I suggested that maybe it wasn’t the space so much, but how he was using it. That didn’t provoke anger or an invitation to leave, so I started offering suggestions… we kicked around some ideas.

Before the day was over, we cleaned out about thousand pounds of accumulated junk from his shelves and cabinets, pulled the old kitchen cabinets out from the wall, screwed them to one another, built a workable base under the cabinets and attached some wheels. We moved the miter saw to one end of the bench. Now when he needs to cut longer boards he can simply roll the bench out into the middle of the garage.

We found his grinder, a couple of electric drills, a portable air compressor, some clamps, and assorted other tools buried under and behind other things. We arranged the tools logically and freed up a lot of space… so much so, that those metal shelves were no longer necessary, so we moved them to the curb… someone will pick them up, perhaps our roving scrap metal collector.

I think my neighbor will soon make some more improvements. A shorter cabinet on wheels, level with his bench, might fit well where those shelves were. He will probably put some pegboard above his bench, and he tells me he is about to buy a small table saw.

Since that fateful Saturday we have put several other strategies to work in his little corner of the garage, and my neighbor is cranking out project after project. I think my new friend is a woodworker again.

Steven Johnson is recently retired from an almost 30-year career selling medical equipment and supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis (although he says home improvement projects and furniture building have been hobbies for most of his adult life).

Steven can be reached directly via email at sjohnson13@mac.com.

|

|

|

|

Check Out These Fine Additions to Your Workshop

|

Top 20 Woodworking Books

Click here for more info

|

Top 5 Leigh Jigs

Click here

for more info

|

Top 10

Veritas Tools

Click here

for more info

|

Top 10 Festool

Power Tools

Click here

for more info

|

|

|

SawStop Professional Cabinet Tablesaw PCS

- Unique brake design detects hand or finger contact with the sawblade, instantly stopping and retracting the blade helping to avoid serious injury.

- 99% dust collection system, robust design and construction and unrivaled fit and finish make it the obvious choice when upgrading your old saw or outfitting your shop with a tablesaw for the first time.

- Get the safest tablesaw on the market into your shop.

Click here for more info

|

|

|

Top 10 Lie-Nielsen Hand Tools

Click here

for more info

|

SAVE

on a Quality

Workbench

CLICK HERE

for more info

|

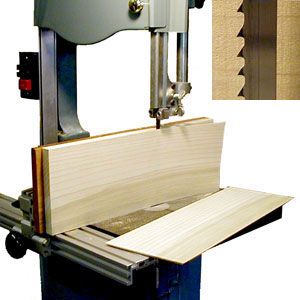

Rikon Bandsaws

Click here

for more info

|

LEGENDARY

Wood Slicer Resawing Blades

Just got a 1/2" Wood Slicer for a project. Put it on, re-tuned the band saw and POW! Right out of the box I'm slicing off veneers of hard maple that measure consistently .030". I'm impressed. The blade is everything it's cracked up to be, sharp, consistent, quiet and it leaves a surface that a couple strokes of a scraper will take care of. I'll be back for more. — Doug F

|

|

|