The Easy Chuck by Easy Wood Tools

by Curtis Turner

Round Rock, TX

Note: click on any picture to see a larger version.

It takes a real innovator to improve upon something that has become widely accepted as a standard. Easy Wood Tools has done just that with their latest product, the

Easy Chuck. The manufacturer promises several unique claims and features. The headlining feature is the Snap Lock Technology (SLT) which promises 30 second jaw changes.

Let’s see if the Easy Chuck lives up to the claims.

First let’s tackle what is included in the package.

|

|

Chuck shown with additional jaws, sold separately

|

-

Chuck with a set of standard jaws

-

Chuck key (hex wrench)

-

Jaw key

-

Spindle washer, replacement set screws and springs

-

Owner’s manual

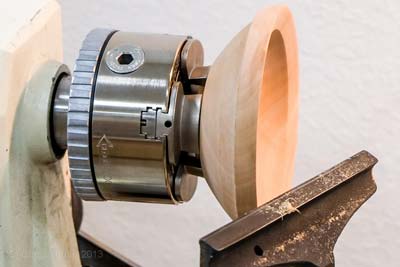

Next, let’s examine the fit and finish of the chuck. Immediately, I noticed the dense mass of the chuck. It is also apparent how well the parts fit together. All parts moved smoothly with a tight tolerance. There were no burrs, rough edges or poorly finished parts. I realize this is subjective, but it does feel well made.

I was eager to test out the process for removing and replacing the jaws. The SLT requires the use of the Jaw Key. This tool is inserted at a slight angle into the small hole on each jaw. A slight push of the tool unlocks the jaw and allows the jaw to slide out of the chuck. This operation is done on each jaw. The jaws are replaced simply by sliding a jaw onto the chuck until the jaw locks into place. You will hear a very clear click sound as it snaps into place. This is done for each jaw.

I removed and replaced jaws several times, before I realized I should test to see if it really takes less than 30 seconds as Easy Wood Tools claims. Then it occurred to me, it really doesn’t matter exactly how fast because it is light years faster than removing and replacing 4 to 8 screws on a regular chuck. It truly is simple; my 7 year old son was easily swapping jaws after watching me only a few times!

|

Typical jaws are attached with screws to the chuck body. The Easy Chuck jaws slide into the chuck body and are held in place by the chuck. While it is not the same, it is somewhat akin to a dovetailed fit. The jaws are case hardened and nickel plated providing an incredibly strong hold. While researching in preparation for this article, I spoke to the folks at Easy Wood Tools about the strength of their system. They told me they broke several testing fixtures without damaging the jaw or snap lock mechanism. They also told me they "...tested a single Snap-Lock mechanism to over 5400 pounds of linear force and the chuck and jaw still worked fine."

Lastly, the jaws have smooth rounded corners which help to reduce injury from contact versus a typical set of jaws.

Chuck key

While the hex patterned chuck key is not a new concept, I think it was a good choice. I find hex keys faster to engage than other types of chuck keys. Also, the hex socket is marked indicating which way to tighten or loosen the jaws. I have to admit that I have almost dropped several bowls by accidently loosening the jaws when I intended to tighten them.

Zoom Ring

This is another innovative idea which simply allows one to finger tighten a blank, glue block or whatever else quickly into place. This means you can use one hand to hold the item in the jaws and initially secure it by tightening the zoom ring. You will always need to perform the final tightening with the supplied chuck key. I found it easier to use this feature with the spindle lock engaged. I think this feature will be more challenging to use if you do not have a spindle lock. The chuck tends to rotate while the zoom ring is being tightened. I may get better at using this function over time.

Spindle washer

I love using a spindle washer. I have one on each of my lathes and highly recommend them. The washer makes it so easy to remove a chuck or face plate. It's fantastic that one is included in the package. Yes, I know it’s not a costly item, but a nice touch by Easy Wood Tools.

Chuck sizes

Currently available in 1" x 8 and 1-1/4" x 8 spindle thread sizes. The inserts are not removable like some chucks. However, an adaptor is available to adapt a larger 1-1/4" x 8 to a smaller 1" x 8 spindle thread.

Jaws

Easy Wood Tools provides several types of optional jaws. They range from long jaws for gripping tenons of about 1/2" to large jaws for gripping blanks up to 24" in diameter and tenons up to 3-1/2" or expand into recesses of 4-1/4".

USA

Lastly, the Easy Chuck is made in America with a 2 year warranty.

So what’s not included?

The only thing missing is a worm screw. I voiced my concern to Craig Jackson at Easy Wood Tools. I understand that they may have a solution later in the year. I know not everyone uses a worm screw, but I do. I think this would be a good item to include or offer as an optional purchase.

Summary

I had been eyeing the Easy Chuck since its introduction. So as you can imagine, I was excited to try out this new chuck. I found it to perform as I expected and feel it lives up to the claims. Easy Wood Tools has developed another quality product that offers several very unique features. The recent price reduction, in my opinion, brings this package more in line with competing products, if you price adjust for additional features. So, should you buy this American made product? Of course, you need to decide for yourself. I would encourage you to handle the chuck and test it out if possible. I know that's not always an option, so I will leave with this thought: I am confident that my purchase of an Easy Chuck will last for many years of hard use and put a smile on my face every time I have to change a set of jaws.

Curtis is a former President of

Central Texas Woodturners, a member of the

American Association of Woodturners, and a member of

Fine Woodworkers of Austin. Curtis teaches and demonstrates nationally for Lie-Nielsen Toolworks. He also teaches for TechShop. He owns a studio where he teaches and works. Curtis lives in Central Texas with his wife and four young children. Take a look at his website at

www.curtisturnerstudio.com or visit his

Instagram: tx_planes.