by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 5)

Previous Page

1

2

3

4

5

Next Page

Waxed Paper vs Freezer Paper – Which Is Best For Woodworkers?

Click on any picture to see a larger version.

Our old sleep-deprived buddy Thomas Edison claims to have invented waxed paper, but amongst his almost eleven hundred U.S. patents, alas, it appears not. Most agree that waxed paper was invented by Gustave Le Gray in 1851 for use in photography, but, like so many things, the story actually goes much further back in time.

Egyptians knew that papyrus could be coated with oil to make it water resistant and semi-transparent. Throughout the middle ages, important messages were often coated with beeswax or other oily non-water permeable substances to protect them while in transit. An important military or political dispatch carried by a runner would be useless if the person's sweat or inclement weather dissolved the message.

So, like many great ideas, waxed paper was an evolutionary advancement, not a revolutionary invention. And since the Great Depression, waxed paper has been a ubiquitous presence in American kitchens, used to preserve and protect food. My earliest school lunch sandwiches were wrapped in waxed paper, not ensconced in ZipLock bags. By the way, we still consider it waxed, but the coating is actually paraffin, and most manufacturers now simply call it "wax paper" which is a misnomer, but I digress…

|

|

Figure 9 - Freezer paper under a glue-up... no stick, no mess

|

Like many other common and almost mundane products we woodworkers have found many, many other uses for waxed paper. In the workshop we use it under glue-ups to protect our work surface and to make cleanup easier. We wipe iron and steel surfaces with it to impart a little protective wax (err, paraffin) or to make things slick. Every woodworker has a roll or two. But lately I have been using freezer paper instead.

Like waxed paper, freezer paper is coated, but only on one side. The commonly available freezer paper we buy is thicker and heavier than waxed paper and the coating is polyethylene, not paraffin. Similar to butcher paper, freezer paper resists liquids and won't stick to a product frozen within its folds. The uncoated side is easy to write on and great for labeling contents.

Freezer paper has also found dozens of other uses. Crafters and quilters use it for making stencils and patterns. It can be used to make iron-on transfers. In fact, transfer paper intended for the inkjet printer is essentially freezer paper cut into printer-size sheets. The first time I used freezer paper in my shop was to make a template for a curved back on a bench. Not being wasteful, I used the scrap pieces under a glue-up and liked it a lot.

So, for the workshop, which is best? At $0.04 per square foot, freezer paper is twice as expensive as waxed paper at $0.02. Freezer paper is over three times as thick at 0.07mm versus 0.02mm. In practical use, a roll of common store-bought freezer paper is a smidge under 18 inches wide and waxed paper is a tad under 12 inches, so covering a bench or work surface with freezer paper takes less strips. But freezer paper retains its curl (likely due to its thickness) more than waxed paper, so the edges need to be taped down so it lies flat.

The cost difference puts a point in the waxed paper column and another point gets awarded for ease of use, since there is no need to tape down the edges. But freezer paper earns a point for thickness (strength) and another for width. Yes, yes, I know wider wax paper is available, but it is more difficult to get.

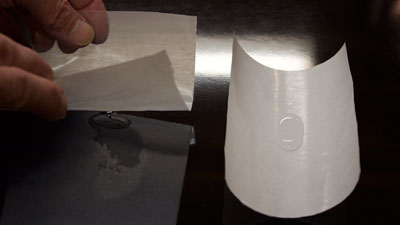

I did several tests to address common woodworking shop uses. First, I dribbled a few spots of

glue on both types of paper to see which would release more easily. I let these dry solid and as

you can see, both flicked off easily, however the glue pulled the paraffin coating off the waxed

paper. With the freezer paper, there is not even a mark indicating where the glue was attached. In

practical terms, this means the freezer paper can be used again and again. If glue drips on an area

where the paraffin was removed from the waxed paper, it will stick tenaciously and you will be

forced to remove bits of paper from your project with scrapers or chisels.

|

Figure 10 - Glue dried overnight pops

cleanly off the freezer paper...

|

|

|

Figure 11 - ...but pulled the paraffin off the waxed paper

|

Second, because I often use either waxed or freezer paper under a project while I am applying a

finish, I did a rudimentary permeability test, first with water, then with mineral spirits. After

only 60 seconds, the water leaked through the waxed paper. The freezer paper did not leak at all.

I left the water on the freezer paper for another three hours without any leak-through. It probably

would have lasted longer, but the test was in my way and I had to move it! Water permeability

earned a point for freezer paper.

|

Figure 12 - Evidence of leakage was immediate and

apparent with the waxed paper

|

|

Figure 13 - After just a minute, there was a pretty large

puddle of water underneath the waxed paper

|

|

Figure 14 - The darker colored wood underneath (far left)

is a clear indication of the mineral spirits leaking

through the waxed paper

|

With mineral spirits, the waxed paper leaked though within three seconds. There was no

leak-through with the freezer paper, however there was a slight bit of coloration change close to

the edge. It looked like the mineral spirits tried to leak through at the edges, but evaporated

before it made it all the way. Add another point in the freezer paper column.

|

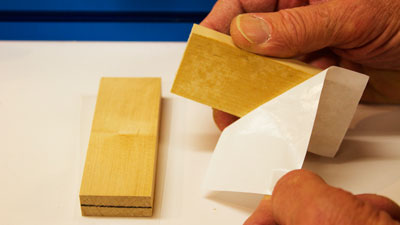

Figure 15 - A coat of Titebond III between a scrap of wood

and the paper will be a tough test

|

|

|

Figure 16 - Both papers released cleanly and easily, but...

|

Third, I glued two scraps of maple to both waxed and freezer paper to see which would have the cleanest "release." As you can see in the photos, both pulled free of the wood easily. However, the waxed paper would be rendered unusable because the paraffin was left behind on the wood.

|

|

Figure 17 - ...the waxed paper could not be reused

|

Even though it is not always necessary to tape down the less-curly waxed paper, I often do, just to keep it from moving around. On both the waxed paper and the freezer paper's shiny (coated) side, the tape peeled off easily. Good news for those of us who frugally try to reuse our paper. On the uncoated paper side of the freezer paper, the tape pulled a few paper fibers loose and I suspect would have taken more had the tape been in place longer. I would call this test a tie, but if I were to make a template from freezer paper, I am confident in taping, removing, and re-taping the template on multiple parts without worry of destroying my carefully made pattern.

Of late, when gluing up multiples like drawer boxes or cabinet doors, I spread out a large sheet of freezer paper, do the glue-up, put the assembled piece in clamps and move it aside to dry. Any stray drips of glue are easily wiped up with a damp paper towel and I am immediately ready for the next glue-up. I recently used the same piece of freezer paper to glue up seven drawer boxes and the paper was still in good shape when I finished. Waxed paper would not have made it through more than two glue-ups.

|

Figure 18 - Painter's tape peeled easily off both the waxed

and freezer papers, but on the uncoated side of the freezer

paper, the tape picked up paper fibers

|

Given the ability to reuse freezer paper multiple times, coupled with its thickness and strength, makes freezer paper a more cost-effective product than waxed paper. It is resistant to fluids, bright white (which helps these tired eyes), and easy to work with. As a bonus, the back (uncoated) side of freezer paper makes great drawing paper. I can make templates/patterns easily. I have also used it as a background for close-up photos, as a temporary window shade, and even as a placemat when forced (privileged) to each lunch in my shop. It is readily available and the roll width is a bonus. Freezer paper has become my go-to product for multiple uses and can be found now under all my glue-ups. If you have never tried freezer paper in your shop, grab a roll… you may become a convert, too!

(Page 3 of 5)

Previous Page

1

2

3

4

5

Next Page

Return to

Wood News

front page