by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 3)

Previous Page

1

2

3

Tool Inventions

There are a few new tools I want, so manufacturers, listen up! There is no way I can guarantee you millions, or even thousands, of sales, but I will guarantee you one… and I'll bet a few other people will buy them, too.

Festool Backpack Dust Extractor

|

Figure 5 - Go anywhere, do

anything with the new

Backpack Dust Extractor.

|

Dust extraction hoses get in my way. The great engineering minds in

Germany (Festool)

and in

Finland (Mirka)

have advanced the current state of the art about as far as they can go. Hoses now have integrated power cords, which greatly reduce the hassle factor, and Festool has now covered their hose/power cord assembly with a fabric that won't snag on, or mar your precious work. Now it's time to think outside the box a little.

Envision a small

Festool HEPA Dust Extractor

that can be worn as a backpack. A twenty-foot (sorry, seven meter) or longer power cord might still necessarily tether you to an outlet, but the integrated dust extraction hose and tool power cord could be short, 4 or 5 feet (1.25 – 1.8 meters?). Instead of snaking a bulky hose all over creation, just go to your work, do what needs to be done, and everything would be relatively self-contained and out of your way.

Think of the possibilities, too, for on-site work. Up ladders and scaffolding, a backpack dust extractor would be easy. No lugging a dust extractor up scaffolding or snaking a hose with you up a ladder. On a job site, there would be no excuse for not hooking up the dust extractor to every Festool tool. Need to rip a section off a long board? The hose won't reach to make the whole cut? With the new Festool Backpack Dust Extractor there will never be any worries about the hose length… whether it is a track saw, router, or sander, the dust collector will follow right along with you while you work.

Given the ever-improving state of brushless DC motors and Lithium Ion batteries, Festool might "knock it out of the park" and make the Backpack Dust Extractor cordless. On my back I could easily carry 3 or 4 lithium ion batteries ganged together to power both the dust extractor and the tool.

If you twist my arm, I'll volunteer to test the new product. You won't have to twist too hard. And the next time I am on top of a ladder sanding a section of crown molding, I will sing your praises.

Woodpeckers Drawer and Cabinet Pull Attachment Jig

Over the years I have had at least five (maybe six) different drawer and door pull alignment and attachment jigs and while they all work to some extent, they all pretty much stink to some extent. After working countless hours to build and install gorgeous cabinets, doors, and drawers, and your customer (or spouse) finally decides on pulls, do you really want to trust this final critical detail to a jig that is "iffy?"

Jigs run the gamut, from cheap non-adjustable plastic to expensive adjustable metal, but they all suffer from one or more confidence-killing flaws.

Woodpeckers

would, I am confident, make one that really works. It would be pretty in its aircraft grade aluminum and red anodizing, and it would be thoughtfully engineered. Drawing is not my forte, but here are some sketches to illustrate the design. Click on the photos to enlarge.

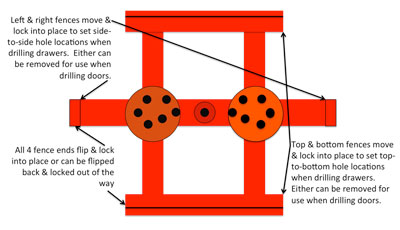

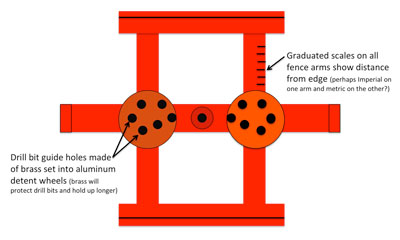

The heart of the jig would consist of two click-stop wheels that turn in unison, stopping on common drawer pull drilling center locations (64mm, 2-3/4", 3", 3-1/2", 96mm, & 4"). No chance of these getting out of adjustment. There would also be a fixed hole in the middle of the jig for drilling single holes for perfectly placed knobs. The whole unit would of course be made of that awesome aircraft grade aluminum that Woodpeckers uses, but each drilling guide hole should include a brass insert so that drill bits and the guide holes last longer.

|

|

Four precision guide arms would set the distance down from the top of the drawer edge, up from the bottom, and center the holes side-to-side or at desired locations via two adjustable centering/independent fence arms. Each of the four guide arms could be removed from the jig. When drilling holes on cabinet doors, two arms would locate the holes precisely. The guide arms would all include graduations in metric and Imperial, and at each end a flip-down lockable fence. If you want to reference off the left face for a drawer pull, flip the fence down on the left side arm. Then flip that fence out of the way and flip the fence down on the right side arm, move the jig, and drill a perfectly located/matched pair of holes for the other pull.

I will also volunteer to test this important new tool. In fact, if asked, I will do a

Product Tour video for Highland Woodworking

and talk at length about the genius of the inventor. Just kidding. But I promise to buy one.

...

The last couple of months we have been looking at ways to quickly and efficiently build kitchen cabinets… well, at least base cabinets. In a

two-part series

we built a basic base kitchen cabinet in two hours. In

last month's video

we quickly built some nice drawers using a drawer lock bit on the router table. In

this month's video

, we look at drawer slides, dissect one to see how it works, and provide some tips and tricks to get them installed correctly. With these tips it is easy to get that perfectly smooth gliding drawer action everyone loves.

...

Next month we are going to put together all these techniques and build a beautiful bathroom vanity. Essentially a bathroom vanity is just like a kitchen sink base, but with different dimensions and (usually) integrated drawers. See you next month!

(Page 3 of 3)

Previous Page

1

2

3

Steven Johnson is retired from an almost 30-year career selling medical equipment and

supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis

(although he says home improvement projects and furniture building have been hobbies for most of his

adult life).

Steven can be reached directly via email at

downtoearthwoodworks@me.com

.

Return to

Wood News

front page