|

The Veritas Power Tenon Cutter creates a clean, round tenon on both dimensioned wood and rough sticks or branches. It also creates smoothly radiused shoulders on the ends of the wood to provide a nice transition from the tenon to the body of the wood leg or stick.

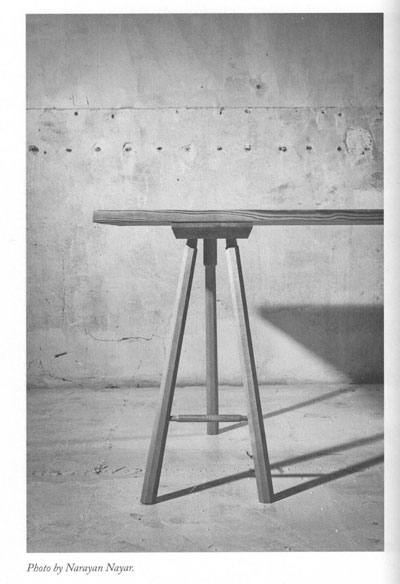

I've been very interested in creating round tenons on the ends of table legs because I've been fascinated with the trestle table described in The Anarchist's Design Book by Chris Schwarz. The book focuses on 'staked furniture' which is basically a stake (eg; leg) that penetrates a block (top) of wood. The key to this is a round tenon on the end of the stake that passes through the top. Below is an example of one end of a trestle table from Chapter 12 of The Anarchist's Design Book. I plan on making this type of table in the near future.

|

Picture used with permission from

Lost Art Press

|

As with all Veritas tools that I have used, they are extremely well made. You can read about the product specifications of the Power Tenon Cutter here.

The cutter comes with an instruction manual as well as a shim and rare earth magnet, which assist in making small adjustments to obtain your desired tenon diameter.

Before I get into describing how the tenon cutter is used, I need to mention that when you open the box you can tell immediately that this is a serious professional level tool. I reviewed the 1" Cutter and was very impressed with its size and mass. The body of the cutter is 3-1/4" diameter at the cutter end and 5-1/2" long and has a significant 'heft'. The other impressive feature is the user manual. I didn't expect that a cutter to make a simple tenon on the end of a stick would come with 7 pages of instruction! It is very well written with numerous tables and illustrations.

Once you get past the two pages of safety rules the instructions discuss:

-

Maximum wood diameters for the different tenon cutter diameters

-

Adjusting the blade in the cutter

-

Adjusting the Shaving thickness

-

Setting the tenon length

-

Taking a test cut

-

Sharpening the blade

-

Troubleshooting

As you can see in the following picture, the back end of the blade is contoured to avoid anything extending beyond the revolving aluminum body. The body has a built-in honing guide for easy sharpening of blades on a drill-press mounted drum sander and the blade is adjustable to cut the exact size of tenon required. The blade can be adjusted slightly using the over-sized adjustment screws. The large screw with the brass ring is a locking screw and the smaller screw on the side is for fine side-to-side adjustment to change the depth of cut. Finally, if the cutter is backed off all the way and is still cutting a tenon that is slightly too narrow, you can use the included brass shim shown in an earlier picture. A piece of this shim can be inserted behind the blade near the locking screw. The shim is 0.010" thick and the maximum tenon size will be increased by approximately 0.020". This is an amazing amount of precision!

So, how does the tenon cutter work in practice? The instructions warn you to ONLY use the cutter in a hand drill or brace. Since the workpiece must be rigidly clamped in line with the equally rigid axis of the drill-press chuck, any misalignment or movement can create high side loads on the tenon cutter, which could cause the shank to fail. You can make minute alignment adjustments with a hand-held drill which eliminates this problem.

First I wanted to try the cutter on a dimensioned piece of wood so I used a 1-12" square workpiece. I beveled the end slightly so it would start into the cutter easily.

To align the cutter with the workpiece there is a built in level. You also make sure the cutter is square left to right by eye.

Once you are ready, you pull the trigger and lean into the cut. You'll be surprised how vibration-free the cutter cuts and how easily it cuts the wood. The mass of the cutter really reduces any vibrations and it throws a lot of chips but with very little to no resistance.

As you can see, even in this soft piece of wood, the cutter creates a very smooth tenon with no tear-out on the end grain. The shoulders are well rounded and there is a smooth transition from the tenon through the shoulder and the body of the workpiece.

I went out in the yard and found a stick that could represent the leg or spindle on a rustic piece of furniture. I clamped this piece to the workbench and attacked it with the tenon cutter.

Because of the size I didn't need to taper the leading edge so it cut very easily. Unfortunately, this was because the diameter of the stick wasn't as large as it could have been. The resulting tenon wasn't as distinctive as it could have been for illustrating purposes but it demonstrates that the cutter would be excellent for cutting tenons for making rustic furniture.

Overall, I was very impressed with the Veritas Power Tenon Cutter. The tenon cutter can be purchased in a wide variety of sizes and is made to the highest of Veritas standards. The mass of the cutter reduces overall vibrations to a minimum and the built-in level makes the cutter very easy to align and use.

Find out more and purchase a

Veritas Power Tenon Cutter

Jeffrey Fleisher has been a woodworker for approximately 20 years and a professional woodworker for the past 6 years. He is the president of his local woodturning club, the Woodturners of the Virginias and past president of the Northern Virginia Carvers. You can see some of the furniture he has made at www.jeffswooddesigns.com. He can be reached by email atfurnmkr@gmail.com

Return to the

Wood News Online

front page

|