5 Fourth Place Winners

Each receives a $15 store credit at Highland Woodworking

4th Place Winner

4th Place Winner

Paul Hoffman's Mobile Tool Cart Stabilizers

Besides using toggle clamps on shop jigs, I have also had success using them to lock and stabilize mobile tool carts.

Click on any picture to see a larger version.

|

|

4th Place Winner

4th Place Winner

Nate Hood's Bandsaw Jig for Perfect Arcs

This is a simple two part jig:

1. A curved notched Fence that is clamped onto your bandsaw table.

2. A curved Sled that rides against the Fence.

Your wood blank gets clamped to the Sled, and since the Sled is

slightly thicker than the Fence, your wood blank rides right over the

curved Fence.

Perfect identical arc cuts every time with no pattern tracing or free

hand cutting!

Click on any picture to see a larger version.

|

|

4th Place Winner

4th Place Winner

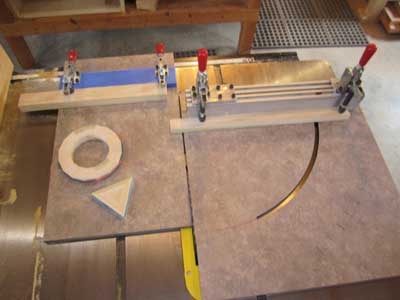

Frank Hamilton's Miter Sled

This is a miter sled I use on my tablesaw to cut the segments I glue together for making segmented bowls and plates. I use the toggle clamps to hold the small pieces safely to be cut on the tablesaw. I also use toggle clamps to hold my stop on this same jig.

Click on any picture to see a larger version.

|

|

4th Place Winner

4th Place Winner

David Lynch's Bandsaw Jig for making

Guitar Pick Cases

I have been making these guitar pick cases for a while now and needed a way to band saw the back of the case off so the grain pattern in the wood matches. With such a small item I needed a way to do this safely. The 1-7/8" vertical Toggle Clamp makes this operation safe and efficient. The plunger pushes on the slope of the ram block and holds the work piece against the fence, while the stop block pushes the piece through the blade and the thin kerf in the stop block makes for a tear free cut at the end. Once the piece has been completely cut off I can safely remove the cutoff piece before retracting the jig back through the blade. The best part about being able to use the 1-7/8" Vertical Toggle Clamp for this jig is, my fingers and hands stay safely away from the band saw blade.

The vertical Toggle Clamp is the perfect choice for this jig since the stopper locks in place and will not push the work piece further forward when the piece is cut off. The adjustable toggle slide and the long arm of the ram block make adjustment easy. The thin strip against the fence which is made when the blade first cuts into the jig's bed, is flexible enough to accommodate wider cuts. The push block is easily removed and other stop blocks can be used for thinner or deeper cuts. Just remember not to cut off the long piece against the fence (under the cut off piece) since this piece prevents the cutoff piece from falling into the table insert hole. This jig was made for a specific purpose, other variations can be used ( moving the position of Vertical Toggle Clamp) for your specific needs.

Click on any picture to see a larger version.

|

|

|

4th Place Winner

4th Place Winner

Tony Profera's Mortising Jig

The accuracy and repeatability of the resulting loose tenon joinery is spot on. I hope this helps or inspires someone out there.

FEATURES:

-

Uses a plunge router loaded with spiral upcut bits. A guide rail slides in a groove on the backside of the jig. I use PC 690 with a plunge base, PC Edge Guide, and 1/4", 3/8" and 1/2" carbide upcut router bits.

-

With this jig the full length of the bit can be used for deeper mortising capability than some other jigs allow. INCRA T-Trak plus permits the lateral stops to be precisely indexed for perfect length mortises.

-

The larger size of this jig makes for easy mortising setup of small and large work pieces alike.

-

Large vertical base plate and vertical slider plate (18" square each) remove for easier storage.

-

Jig top plate is made from a scrap of Corian solid surface material. It's dimensionally stable and the router base plate slides very easily on it (and it looks cool to me). A piece of 3/4" plywood would work just as well as a top surface.

-

The Jig's base "wings" extend 2 1/2" on each end to permit easy clamping to a workbench or shop table. Bench vice and dogs could be used to secure the jig as well.

-

An adjustable toggle clamp fixture is used to allow any work piece size to be clamped firmly near center. The toggle clamp is mounted to a 3/4" plywood fixture that slides up/down to adjust where clamping pressure is put on the work piece. This significantly reduces any movement or vibration when routing and makes for very accurate and perfectly fitting loose tenons.

BENEFITS:

-

You decide the thickness of your tenons by bit diameter.

-

Lateral stops (to limit router travel side to side) is very easily set.

-

Ability to cut mortises on the edge of a board as well as on the ends.

-

No additional base plate is needed to be attached to the router (only an edge guide).

-

Amazingly fast, accurate, clean, and repeatable mortises. Overall: a joy to use.

Click on any picture to see a larger version.

|

|

|

Return to Jig Contest Winners Front Page

Go to

Highland Woodworking Home Page

|

|