Make a Small Parts Cut-Off Sled

by Fred Kachelhofer

Barnesville Woodturners

Safety should be the prime consideration in any shop. The cutting of small parts always causes great concern because of the close proximity of the hands to the saw blade. I tried cutting parts on the radial arm saw using auxiliary devices such as wood blocks to push against the fence to hold the piece in place. While this solved the problem of keeping my hands away from blade, it did not fully address positioning the piece for an accurate cut.

The pieces I wanted to cut were pen blanks about 3/4" square, ranging in length from about 1-3/4" to 2-1/2". Cutting the blank too short of course means it is a total loss. If the blank is too long, then time is lost trimming it to the proper length using a barrel trimmer. What I needed was a safe way to hold the piece at a precise length to make a quick and efficient cut. I could see no solution on the radial arm, so I went to the sled idea on the table saw.

The completed solution is shown here. It is simply a piece of plywood mounted

with two runners in the slots on the table supporting a guide, hold-down and

push handle. I wanted a way to precisely move the measuring block, hence the

black knob on the left end of the sled. For those who do not need this

precision, then the building of the sled is much simplified. I used cherry for

the upper pieces since it was some scrap I had on hand at the time. Any good hardwood

would work here. The two holes in the sled at the front are for storing onto

matching dowels on the wall.

The completed solution is shown here. It is simply a piece of plywood mounted

with two runners in the slots on the table supporting a guide, hold-down and

push handle. I wanted a way to precisely move the measuring block, hence the

black knob on the left end of the sled. For those who do not need this

precision, then the building of the sled is much simplified. I used cherry for

the upper pieces since it was some scrap I had on hand at the time. Any good hardwood

would work here. The two holes in the sled at the front are for storing onto

matching dowels on the wall.

To start construction on the sled, cut two pieces that will fit into the slots on

the saw. I had some plastic type of material that was almost friction free to

use, but any good hardwood should work here. If you are using hardwood, be sure to

wax it to help reduce friction in the slots. Drop the slides in the slots and

position the plywood over the strips. My plywood base is approximately 14" x 25

-1/2". You can see it might be oversized for what you need. It can be smaller.

Using

a square in the slots, or what ever method you prefer, square the plywood to the

slots/blade and attach to the slides.

For reference, the three pieces that make up the top pieces are:

• 3/4" x 3" x 25-1/2" for the piece supporting the hold-down and handle

• 3/4" x 2" x 10" for the slide

• 3/4" x 2" x 15-1/4" for the back slide support

Let me emphasize here that all these dimensions are for reference only. You

should use the material you have on hand to make the sled. Change the dimensions

to suit your needs.

Attach the long piece to the plywood, squaring to the blade back about 5" to 6"

from the front of the sled. Place the slide piece in front of the long piece and

fasten the back slide support making sure the slide can move freely from left to

right.

Using the picture at left for reference, cut a slot in the slide about 1/4" wide,

leaving about 1" to 1-1/2" of wood on each end to keep from splitting during use.

Mount the slide using a hanger bolt shown at the left. A hanger bolt has a wood

thread on one end and a machine screw on the other end. Position the slide as

close to the blade as you think your shortest cut will be and then place the

screw at the end of the slide slot at the end furthest from the blade. You will

then be able to cut a piece from this setting to the distance of the length of the

slot.

Using the picture at left for reference, cut a slot in the slide about 1/4" wide,

leaving about 1" to 1-1/2" of wood on each end to keep from splitting during use.

Mount the slide using a hanger bolt shown at the left. A hanger bolt has a wood

thread on one end and a machine screw on the other end. Position the slide as

close to the blade as you think your shortest cut will be and then place the

screw at the end of the slide slot at the end furthest from the blade. You will

then be able to cut a piece from this setting to the distance of the length of the

slot.

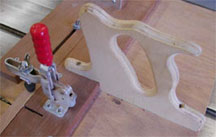

I found a handsaw that had a comfortable handle on it and transferred the

outline of this to a piece of plywood. I then made a projection at the front and

back of the handle to place a screw. I also notched the front of the handle to

fit around the long piece. I then used a round-over bit on the router to break

the sharp edges for comfort. I positioned the saw handle where it would be

between the two slots to minimize binding when pushing and pulling. I then added

a hold-down just to the right of the saw kerf to hold the pieces while being

cut.

I found a handsaw that had a comfortable handle on it and transferred the

outline of this to a piece of plywood. I then made a projection at the front and

back of the handle to place a screw. I also notched the front of the handle to

fit around the long piece. I then used a round-over bit on the router to break

the sharp edges for comfort. I positioned the saw handle where it would be

between the two slots to minimize binding when pushing and pulling. I then added

a hold-down just to the right of the saw kerf to hold the pieces while being

cut.

Using the Sled

To use the sled, I position the reference piece on the sled and move the slide

into position and lock it down as shown at the left. In this case I use the tubing

and do not have to make any measurements. I set the slide back the distance I

want for extra length for the barrel trimmer. With that done, I make a squaring

cut as shown below left. Note that my left hand is safely away from the cut.

To use the sled, I position the reference piece on the sled and move the slide

into position and lock it down as shown at the left. In this case I use the tubing

and do not have to make any measurements. I set the slide back the distance I

want for extra length for the barrel trimmer. With that done, I make a squaring

cut as shown below left. Note that my left hand is safely away from the cut.

The piece is then moved to the right and the hold-down locked in place. Make

sure there is no sawdust or debris in the way of seating the piece in place.

Make the cut, pull the sled back, remove the piece and then position for a new

cut or squaring off another end, etc.

The piece is then moved to the right and the hold-down locked in place. Make

sure there is no sawdust or debris in the way of seating the piece in place.

Make the cut, pull the sled back, remove the piece and then position for a new

cut or squaring off another end, etc.

At this point we have positioned the slice by loosening the wing nut and sliding

the adjustment bar without the aid of a screw adjustment. I might suggest here

that if you want to use this method, consider adding a small knob at the right end

of the slide to help with adjustment.

At this point we have positioned the slice by loosening the wing nut and sliding

the adjustment bar without the aid of a screw adjustment. I might suggest here

that if you want to use this method, consider adding a small knob at the right end

of the slide to help with adjustment.

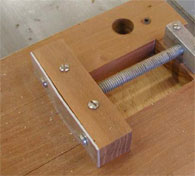

If you would like to have the ability to make very fine adjustments, you can add

a screw adjuster as shown in the pictures. To make this addition, you will need

to take a piece of steel, aluminum or brass about 1/2" wide by 5/8" high and 1-1/2"

long and drill and tap for a 3/8"x16 all-thread rod about 6-1/2" long.

Mount the piece on a block of wood at the right end of the sled as shown at

right. The black knob in the picture is from an old tool that was scrapped and

is held in place with a jam nut. This is used for the adjustment knob.

If you would like to have the ability to make very fine adjustments, you can add

a screw adjuster as shown in the pictures. To make this addition, you will need

to take a piece of steel, aluminum or brass about 1/2" wide by 5/8" high and 1-1/2"

long and drill and tap for a 3/8"x16 all-thread rod about 6-1/2" long.

Mount the piece on a block of wood at the right end of the sled as shown at

right. The black knob in the picture is from an old tool that was scrapped and

is held in place with a jam nut. This is used for the adjustment knob.

Next take a nut and turn it round. On second thought I realized that the nut

need not be turned round, but the hole to receive it must be a larger diameter to

compensate. Drill a hole in a block of wood (in this case 1" x 1" x 3-3/4") for

the nut. This is where great caution must be taken in drilling the depth of the

hole. It needs to be the exact depth of the nut, or else it will create slack in the

movement of the block. When the hole is the appropriate depth, drill through for

the all-thread rod. Note that the block is long enough to ride over the two

slide guides, but the block is screwed to the slide. Note that the center

distance of the holes from the bottom in the two blocks must be the same in both of

the blocks for alignment purposes.

Next take a nut and turn it round. On second thought I realized that the nut

need not be turned round, but the hole to receive it must be a larger diameter to

compensate. Drill a hole in a block of wood (in this case 1" x 1" x 3-3/4") for

the nut. This is where great caution must be taken in drilling the depth of the

hole. It needs to be the exact depth of the nut, or else it will create slack in the

movement of the block. When the hole is the appropriate depth, drill through for

the all-thread rod. Note that the block is long enough to ride over the two

slide guides, but the block is screwed to the slide. Note that the center

distance of the holes from the bottom in the two blocks must be the same in both of

the blocks for alignment purposes.

Now take a piece of aluminum or steel plate and cut it to fit the size of the

block and drill two holes to mount over the nut and rod assembly. Now when the

knob is turned to advance the slide, it will push against the metal faceplate

and when turned to retract, it will pull back against the block of wood. This

will give a very precise method for positioning the slide in relation to the

blade.

Now take a piece of aluminum or steel plate and cut it to fit the size of the

block and drill two holes to mount over the nut and rod assembly. Now when the

knob is turned to advance the slide, it will push against the metal faceplate

and when turned to retract, it will pull back against the block of wood. This

will give a very precise method for positioning the slide in relation to the

blade.

I have found this to be a very safe, efficient, accurate, fast way to cut short

pieces. It takes about one minute to place it on the saw. It takes another

couple of minutes to adjust the length and then I can cut three or four pieces a

minute. Removing the sled from the saw takes about another minute. I have two dowels on

the wall to store the sled when not needed.

I have found this to be a very safe, efficient, accurate, fast way to cut short

pieces. It takes about one minute to place it on the saw. It takes another

couple of minutes to adjust the length and then I can cut three or four pieces a

minute. Removing the sled from the saw takes about another minute. I have two dowels on

the wall to store the sled when not needed.

Fred can be reached at

kplus10@bellsouth.net

for ideas or comments.

Return to

Wood News

front page