Q&A

Question:

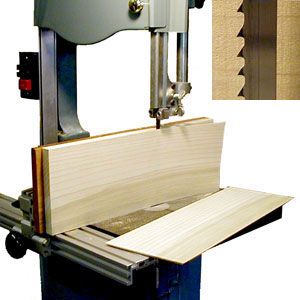

I have and dearly love my 105"

Wood Slicer resawing blade

. I and perhaps others could use some

ideas about what to look for regarding when it's time to replace it.

I'm a segmented turner and cut almost exclusively exotic hardwoods, so I expect the cutting to be

slow on denser woods like rosewood and ebony.

Any tips? Burning, poor finish, twist???

Answer:

In general terms, a cutting edge is dull and should be replaced when your cutting results no longer

meet with your satisfaction. That being said, many of us will continue to use a blade even though

it has become dull. Factors such as time constraints, availability of replacement and budgetary

factors all weigh in and contribute to overusing a cutting edge past its prime.

When bandsawing with a dull blade, you feed slower and push harder. This can get you to the end of

the task at hand, but you should get a sharper blade back on the saw ASAP. No better way to ruin

your day than to push something into the moving blade that doesn't belong there (like a finger!).

Keep in mind that cutting exotic woods like rosewood, ebony, teak and such are going to dull blades

faster than cutting standard, kiln dried, North American hardwoods and softwoods. Even impulse

hardened steel like in the Wood Slicer will suffer the dulling effects of exotics in short order.

It is like the difference in using a HSS router bit and a carbide router bit. High speed steel may

be hard compared to some tool steel, but it pales in comparison to carbide for longevity.

Unfortunately, carbide tipped bandsaw blades are really expensive and would not cut as smooth as a

Wood Slicer.

Keep in mind that cutting exotic woods like rosewood, ebony, teak and such are going to dull blades

faster than cutting standard, kiln dried, North American hardwoods and softwoods. Even impulse

hardened steel like in the Wood Slicer will suffer the dulling effects of exotics in short order.

It is like the difference in using a HSS router bit and a carbide router bit. High speed steel may

be hard compared to some tool steel, but it pales in comparison to carbide for longevity.

Unfortunately, carbide tipped bandsaw blades are really expensive and would not cut as smooth as a

Wood Slicer.

What we recommend with the Wood Slicer is that you use it only for the rigors of resawing and avoid

dulling the band with the daily off-cutting done in a shop. Avoid plywood and MDF as well. The

glues in these products are quick to dull non-carbide steel. Save the sharpness of the Wood Slicer

for the rigors of resawing and use lower priced blades for your general purpose cutting. Also

keeping a blade clean

and removing built up pitch and baked on crud can help with blade life.

The very minimal set of the Wood Slicer is partly what makes the finish cut turn out so smooth, but

it can make the cut drift and wander as the blade loses sharpness. Burning, deep lines in the

finish cut and the need for excessive feed pressure when cutting are other factors that serve to

signal you that it may be time for a replacement band.

Return to

Wood News

front page