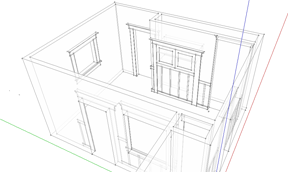

Last month we started the process of designing a kitchen renovation using

SketchUp

. We started the

process by modeling the building environment, showing the placement of doors and windows,

then adding moldings and door and window casings. We also saw how to use product documentation

and images from the Internet to make models of appliances and fixtures not already available in the

3D warehouse.

Last month we started the process of designing a kitchen renovation using

SketchUp

. We started the

process by modeling the building environment, showing the placement of doors and windows,

then adding moldings and door and window casings. We also saw how to use product documentation

and images from the Internet to make models of appliances and fixtures not already available in the

3D warehouse.

This month we will see how to make cabinets for the kitchen, create flat panel as well as glass

panel doors, then make drawers and add hardware to finish your kitchen design. The cabinets we are

modeling in this example communicate a good level of detail but are not meant to illustrate

construction details. Using the overall dimensions of each cabinet I normally create separate models

for more precise measurements and assembly

views. Once familiar with the techniques described here, you should have no problem creating all

types of cabinet models.

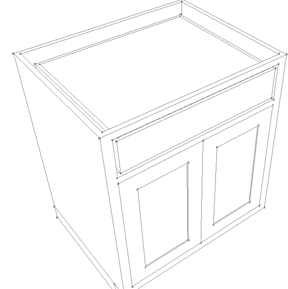

Base Cabinets

I tend to start with cabinets that have to be a predetermined width like sink bases or microwave

cabinets, then build the remaining units.

I tend to start with cabinets that have to be a predetermined width like sink bases or microwave

cabinets, then build the remaining units.

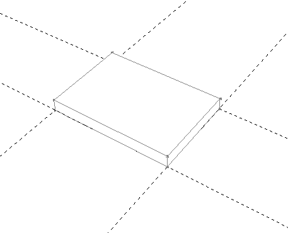

• Start by using

construction guides

to define the dimensions of your cabinet. A

standard base cabinet is 24" deep, so your base should be 21" deep to allow for a 3" toe kick.

• Use the

rectangle tool

to draw the base of your cabinet.

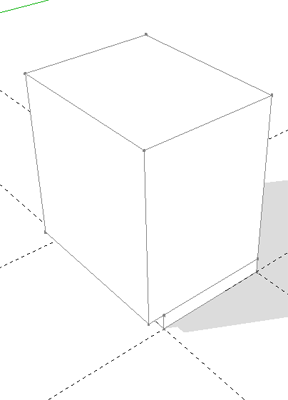

• Select the

push/pull tool

and raise the base 3".

NOTE: To model accurately, you need to use the

measurements box

to enter values for the functions you

perform when modeling. If you do not see the measurements box at the bottom of your screen, you can

enable it by choosing

VIEW>TOOLBARS>MEASUREMENTS

from the toolbar at the top of your screen.

NOTE: To model accurately, you need to use the

measurements box

to enter values for the functions you

perform when modeling. If you do not see the measurements box at the bottom of your screen, you can

enable it by choosing

VIEW>TOOLBARS>MEASUREMENTS

from the toolbar at the top of your screen.

• With the push/pull tool still selected, press the control key. You can see this will

toggle on and off a "+" symbol next to your cursor. This allows you to create a new face. I think

this is especially useful for woodworkers as it helps to define where joints would occur. With the

"create new face" option on, pull the base up 31.5". This should bring the height of the base

cabinet up to 34.5" (36" standard counter height less 1.5" for the counter top)

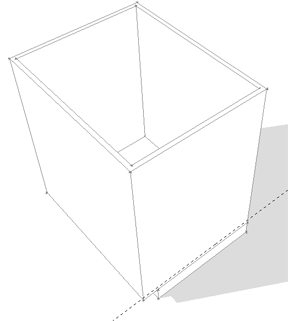

• Push/pull the front of the cabinet forward 3".

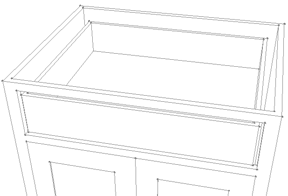

• With the

offset tool

, hover over the top of the cabinet. You will see the edges that

will be affected by the tool. Offset towards the inside of the cabinet 3/4". This defines the

sides, face frame, and back of the cabinet.

• With the

offset tool

, hover over the top of the cabinet. You will see the edges that

will be affected by the tool. Offset towards the inside of the cabinet 3/4". This defines the

sides, face frame, and back of the cabinet.

• Push/pull the new face down 30.75" to leave a 3/4" bottom in your cabinet.

• Push/pull the new face down 30.75" to leave a 3/4" bottom in your cabinet.

• Using construction guides, lay out the locations of the openings in the front of your

cabinet.

• Choose the rectangle tool. Using the construction lines you made, draw rectangles where

the drawer and door openings will be.

• Push/pull the faces through to create the openings.

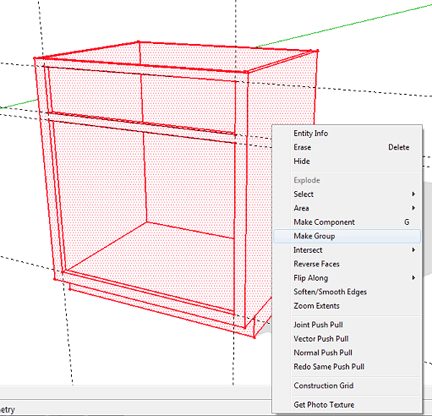

• You should now make the carcase a group by

triple clicking the object to select

all

the geometry, right click, and choose

Make Group

from the drop down menu.

Doors

These steps will describe how to create flat inset panel and divided light glass doors. Once

familiar with the process you should be able to create many different door styles.

These steps will describe how to create flat inset panel and divided light glass doors. Once

familiar with the process you should be able to create many different door styles.

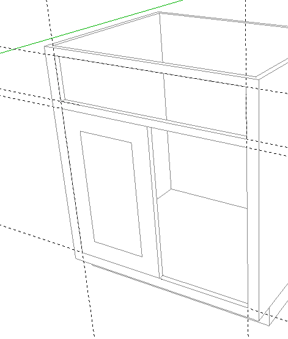

• Using the rectangle tool, draw your door starting from the upper left hand corner to

the center point along the bottom of the opening. (

SketchUp

will infer to center points

and end points as your cursor passes over them).

• Push/pull the face of the door in 3/4" for flush inset doors or out for overlay

doors.(For overlay doors you will also need to push/pull the edges to create the amount of overlay

for your specific application.)

• Push/pull the face of the door in 3/4" for flush inset doors or out for overlay

doors.(For overlay doors you will also need to push/pull the edges to create the amount of overlay

for your specific application.)

• For frame and panel doors, use the offset tool on the face of the door to determine the

width of your rails and stiles, then push/pull the face of the panel in 1/4" to 3/8".

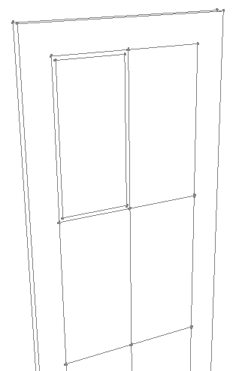

• For glass doors, begin the same way. Once you have offset the width of your rails and

stiles, right click on the line that is the inside edge of the stile of your door. Choose

Divide

from the drop down menu. This will create more or fewer divisions as you move up and down the line.

As I mentioned, center points are always recognized, so dividing the rail is not necessary unless

you plan on having more than two panes of glass from side to side.

• With the line tool, draw lines dividing the space based on the divisions you set up in

the previous step. These will be the center lines of the glass mullions.

• With the line tool, draw lines dividing the space based on the divisions you set up in

the previous step. These will be the center lines of the glass mullions.

• Choose the offset tool. With your cursor in one of the panes, offset 3/16" to 1/4". Do

this in each one of the divisions until you have created offset rectangles in all of the

panes. (Double clicking with the offset tool creates the same offset as the last time the tool was

used).

• Erase the center lines you created in the previous step.

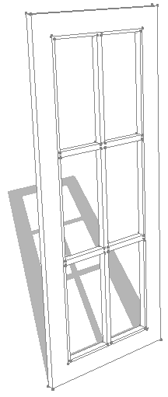

• Push/pull the area where the glass will be located through creating the divided

lights, then push the mullions back about 1/4".

Make all the door geometry created thus far into a group

.

• Push/pull the area where the glass will be located through creating the divided

lights, then push the mullions back about 1/4".

Make all the door geometry created thus far into a group

.

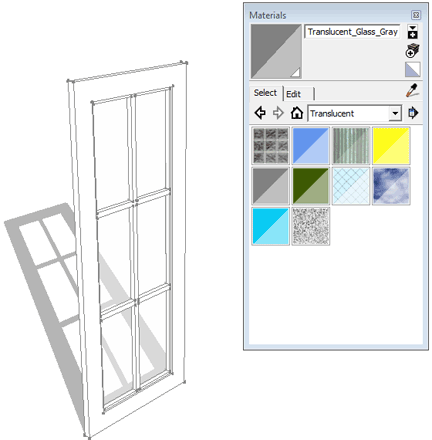

• To make the glass, draw a rectangle onto the back of the whole grille.

• Choose the

paint bucket/materials

tool. A dialog box will appear. Click to expand the

material drop down menu and choose

Translucent

from the material options. Select one of the

materials (I use the greenish type glass) and apply the material to the rectangle you made.

• With the selection tool, while holding the shift key to select multiple items, pick the

"door" group and the glass. With your cursor over the selections, right click and choose

Make Component

from the drop down menu. This should be a component and not a group because you are going

to have multiple instances in your model.

• With the selection tool, while holding the shift key to select multiple items, pick the

"door" group and the glass. With your cursor over the selections, right click and choose

Make Component

from the drop down menu. This should be a component and not a group because you are going

to have multiple instances in your model.

• Select the new component and

Move a Copy

over to create a second door.

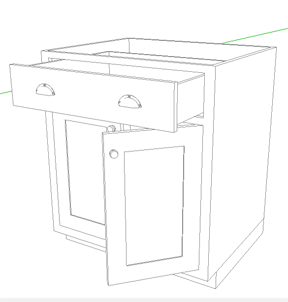

Drawers

Drawers

In this example we will model a flush inset drawer face. As before, once you understand the

concepts presented you should be able to create overlay drawer fronts using similar steps.

• Start by drawing a rectangle that matches the drawer opening.

• Using the offset tool create the drawer box by offsetting by 1/2". Depending on the

type of drawer hardware you use, you can adjust the clearance you need, but this should be accurate

enough for the purposes of this model.

• Select and delete the face around the drawer box.

• Push/pull the drawer box into the opening about 22".

• With the offset tool, double click the top of the drawer box repeating the last

measurement of 1/2" (a typical drawer material thickness).

• Push/pull the new face created down approximately 1/2" shy of the total height of the

drawer box, leaving the drawer bottom.

• Push/pull the new face created down approximately 1/2" shy of the total height of the

drawer box, leaving the drawer bottom.

• Select the drawer and make it a group.

• For the drawer front, draw a rectangle matching the drawer opening as you did before.

• Push/pull the rectangle forword 3/4" to make the drawer front.

• Select the drawer front and the drawer box and make them a group or component.

• Select the drawer group/component. Using the move tool, click once on the corner of

the drawer front and click a second time on the corresponding corner of the drawer opening to place

it in the correct position.

To finish up your model, go to the

3D warehouse

to find the perfect knobs and drawer pulls . I

like these

bin pulls

for most of my drawers. I hope you find these techniques useful, whatever your

project. If you have any questions or article requests, please don't hesitate to

send me an email

.

Sean Headrick, a former Atlantan once seen frequently at Highland Woodworking, now lives

in San Jose, California where he does woodworking and design.

His website is

www.headrickdesigngroup.com

.

Sean was

interviewed by Wood News

in 2007.