Understanding, turning and enjoying spinning tops

by Federico Kuhlmann

Mexico City, Mexico

Spinning tops are everywhere

A spinning top is a solid piece of material (wood, metal, plastic, rubber), which receives energy from an external source, so that it can start spinning and maintain its movement for some time. The top can receive its spinning energy from a variety of sources, and most common being twisting fingers (for finger spinning tops) or a cord or string wound around the top. This second variety initiates its spinning movement with a rapid release of the cord or string from the top body by throwing it to the ground or strongly pulling the cord or the string. Other tops are set in motion by moving the palms of the hands against each other while holding the top shaft between them, using whips or using mechanical devices (like in the pump tops frequently seen in toy shops).

Spinning tops are amazing indeed. Think about this: if a top lies on a table motionless, it is boring. However, once you set it in motion, you can observe its magical behavior, often unimaginable by us, defying the laws of physics, singing or humming, jumping, moving around or just quietly "sleeping", in an apparently placid immobility. New "high-tech" tops, enriched by electronics, can even generate beautiful light patterns when they are in motion.

Ever since mankind started observing spinning tops appearing in nature, they have captivated our attention and developed our imaginations. They can be large (such as celestial bodies like the earth), or they can be small, like finger spinning tops. Applications for spinning objects are found not only in toys and games (tops, yoyos, diabolos, dreidels), but also in a variety of engineering related apparatuses, like the gyroscopes used in inertial navigation. Spinning phenomena are also observed when throwing oval shaped footballs (where rotation is crucial for allowing the receiver to catch the ball; a wobbling ball is much more difficult to catch). This spinning phenomenon is equally important for bullets to be aimed accurately at a bull´s eye. The spinning principles are also crucial for bicycle riding. Many countries claim to be the inventors of toys based on spinning tops, but there exist numerous pieces of literature documenting their presence many centuries ago in all the continents of the world: clay, ceramic and wooden tops where found in former Mesopotamia, and date back as far as 3500 years, and there are many references to spinning tops in classical Greek literature.

What makes them so fascinating?

When I first became a fan of spinning tops and started turning them, I learned many fascinating facts about this hobby. First, since I had been an amateur woodworker for many years, always reluctant to throw away even small pieces of exotic or tropical woods, I had baskets full of beautiful hardwood pieces. So now, instead of having ugly looking, odd shaped pieces, I can make them nice-looking and in addition, give them spinning properties. Second, once you know the tricks of the trade, it can take you only a few minutes to complete a spinning top, all the way from scrap wood to finished top. Short, fast projects are nice to do, when time is a scarce resource. Third, you will be amazed once you have turned many tops and start giving them away, how people react to these sometimes "poor boy's" toys and some other times "noble" desk decorations. The fact that you can shape the top you are turning in an almost infinite number of ways allows you to apply your imagination and try out many different heights, diameters, decorations on the axis and transitions between axis and body.

Some physics

Spinning tops are rigid bodies which usually have radial symmetry, which means the mass is evenly distributed around the top's stem or axis, which allows the top to maintain its spinning movement for some time after it receives energy from the external source. Radially symmetric spinning bodies appear often in nature and you can observe many different special effects: try spinning an egg (boiled, please!), an Acorn nut (this is very amazing) or a Eucalyptus seed. There even exist objects in nature which do not have common symmetry properties, but exhibit strange behaviors when spun. Have you ever seen a "celt", sometimes known as a "rattleback", which spins only in one direction, but stops and "complains" with a rattling noise when you attempt to spin in the other direction?

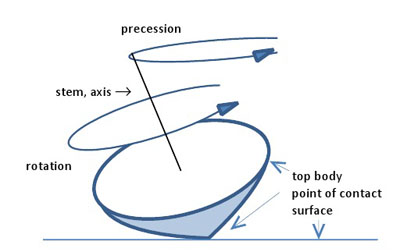

Once a top is spinning, its movement depends on its characteristics. For example, if the top is well balanced and has a single, sharp point of contact with the surface it is spinning on, then there are two easily observable superimposed movements: a rapid rotation about the top's axis (spinning) and a second movement, called "precession", which is the movement of the highest point of the top's axis; this point moves in imaginary circles, while the axis travels on an imaginary surface with the shape of a cone

1

. Precession is usually much slower than rotation (for example, the rotation period of the earth is close to 24 hours, while its precession period is close to 26000 years). In addition, if the top is not accurately balanced or if the point of contact with the surface changes with time (for example, if instead of a single contact point it has a spherical contact surface), then the point of contact will move around the surface, tracing on it helicoidal or circular trajectories, and originating a displacement of the whole spinning top with respect to the surface. Displacement of the top on the surface occurs when the point of contact is not aligned with the rotating axis, in which case the top can display a "jumping" behavior. External forces also act on the top: after spinning for a while, rotation is inhibited by the friction due to the contact between top and spinning surface and to the surrounding air resistance. They both decrease the spinning speed and the precession period, and eventually lead the top to a rest.

The movements of a top rely on the so-called gyroscopic effect: a spinning body will try to oppose anything which tends to modify the direction of its axis of rotation. This can also be explained in terms of the angular momentum (an indicator of an object's resistance to change its spinning characteristics), which is the product of the top's moment of inertia and its angular velocity. This quantity is conserved in the absence of external perturbations. For example, you will notice that the rotating speed of a figure skater increases if her arms are closer to her body than if they are stretched out.

The movements involved in a spinning top are illustrated in the figure below:

|

|

The top, its components, its movements

|

Spinning movements depend also on the shape of the top and on its mechanical properties, such as the density of the material of which the top is built, the weight distribution with respect to the height, the location of its center of gravity, the largest diameter of the spinning body, the precise shape of the contact point or surface, the length of the axis, the distribution of its mass with respect to the axis, among other factors. Developing a mathematical model for a spinning top and its movement can be quite a difficult task, but fortunately, no such model is needed in order to turn beautiful, amazing tops. What we need is a few very simple rules to select the wood we will be using, the most adequate chucking method, the shape we will give them according to the dynamics we would like it to have, the tools we recommend, and the finishing method for our finished top.

Wood type, sizes, shapes

In the following, I will refer mainly to finger spinning tops, even though most of the ideas can be used in other types of tops, like the ones which require a cord to start spinning. The first selection you have to make is the material that you will be using: you must keep in mind that the harder (or denser) the piece of wood you use, the easier it will be to turn a top and the nicer the resulting top will be. For example, rosewood, cocobolo, purple heart or similar tropical hardwoods are ideal for turning tops. And once finished, they look amazing.

As far as size is concerned: every top has two very easily distinguishable components, the stem and the body. The stem length is determined by the length of the blank, while the body size will be determined by the width of the blank. Keep in mind that the finished top will be approximately 1" shorter than the original blank, because you have to subtract from the blank length the waste which will be originated by the chucking needs.

You will quickly find that there are no fixed rules for the dimensions you use, so for this example, let's start out with a 3" long square with a base of 1.5" by 1.5". The maximum dimensions you can expect for your top from this blank are a length of 2-2.5" and a body diameter of 1.5". When you start turning, try to concentrate the body mass on the lower part of the stem, and try to keep the body diameter as large as you can, because this will give your spinning top a large angular momentum and good stability resulting in long spinning times. For finger spinning tops, a length of 2" to 4" is reasonable, but the maximum diameter of the body should be kept smaller than 2". The total mass of the top must be kept small, because otherwise you might not be able to spin it just with your two fingers. Therefore, larger body diameters will force you to turn thinner bodies.

Chucking, turning, tools

In turning a spinning top, I use the between centers spindle turning method almost exclusively. Start by taking your square blank, use a spur center on the head side and a live tail center, and use a roughing gauge to shape approximately 0.5-0.75" of the tail into a cylinder, which will allow you to rechuck the blank using a jaw chuck. Now change your head chuck to a 3 or 4 jaws chuck, rechuck the blank and use a live tail center to support the piece while you turn it. Even though you can turn the top's point (or tip) in either one of the extremes and the shaft in the other, I recommend having the longer piece (the shaft) pointing towards the tail, since this will provide more stability while turning.

The next step is pure fun: unleash your creativity and start shaping the top, its stem, its body and the transitions between them. Use different sized spindle gouges and chisels, suitable for the dimensions of your top, but only use very sharp tools. In my experience, it is easier to turn the shaft first, followed by the body, and finish with the point. Be very careful when the stem becomes thinner to avoid breaking it. Keep in mind that you must allow some space to part the top when it is close to finished, and to give the final shape to the point on the head side. This is very critical because an imperfect point will cause wobbling or other unpleasant movements when you start spinning the top.

Parting, finishing and enjoying

Before you remove the almost finished top from the lathe by parting it from the waste side (which is normally held to the lathe by the chuck), you must shape the point (or tip) using great care: the spinning properties and stability of the top depend greatly on this point. Ideally, it must be sharp and perfectly aligned with the rest of the shaft. If it is not, then the top will jump while turning. Additionally, the top will not have sufficient support on the spinning surface and will likely move around the surface.

Before parting the top from the waste, I usually sand the top thoroughly and seal it using shellack or several coats of wax, to avoid stains from your fingers. Finally you can part the top: remove any remaining waste on the tail side (the stem) and use a parting tool or a skew chisel to part it from the waste on the head side; use only very small incremental cuts, so that the point will not be distorted. If the first few times you spin the top it jumps or moves apparently uncontrolled, do not worry: the tip is probably rough or not aligned with the axis. Try this: smooth out imperfections of the tip by spinning the finished top a few times on a sandpaper surface: a few times on medium grit, followed by a few times on fine grit, finishing with a few times on very fine grit, before you apply the last coat of wax.

Once you have turned a few or a few dozen tops, you will probably be familiar with the basics, and ready for more sophisticated styles and ideas. Try to turn tippee-tops (the ones which turn upside down, once they are spinning), or inside-out tops (which are obviously hollow), or try putting magnets into the top’s body, so that it can interact with metallic pieces like paper clips, or turn tops with lose rings, or combine differently colored woods (almost like laminated tops). If you use highly valued tropical wood pieces, and you do not want to waste most of it, rough turn the stem, cut a disk on a band saw with the diameter you desire for the body, drill the disk so that you can insert and glue the stem, and then start turning, by chucking the stem on a jaw chuck and using a live tail for stability.

You will find out that an infinite number of possibilities exist to keep experimenting and having fun. As a dessert for this short contribution, I give you pictures of a small sample of my tops.

You can email Federico at

fkuhlmann51@gmail.com.