by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

Product Showdown!!!

Click on any picture to see a larger version.

A lot of the products woodworkers use on a regular basis never get an in-depth review, let alone a real toe-to-toe showdown test. Never fear, your Down to Earth Woodworker is going to fill this gap in our collective knowledge. For the next few months we will compare, test, review, and opine about these ubiquitous, un-sexy, everyday commodities and shed some light on which ones are really best for woodworkers.

|

Figure 12 - The roll on the right certainly

looks like a better value...is it?

|

Chances are very, very good that you have at least one roll of plain white paper towels in your shop… maybe more. Chances are equally good that you also have a roll or two of those blue paper "shop" towels. If you are like me, you always grab a "cheap" white paper towel to clean the glue off your fingers or to wipe away a spill, and you choose those "more expensive" blue paper towels to degrease a machine, wipe on your rust preventive liquid du jour, dry and clean your blades while sharpening, or maybe even to wipe on a quick coat of finish (gasp!).

Your impressions, like mine, are probably that the blue paper towel roll is smaller than regular paper towels, the rolls are more expensive, that they are essentially "lint free," and they are thicker. They look stronger and they feel softer, too. The fact is, most of us "save" the blue paper towels for special purposes. I'm fairly comfortable that these are near-universal attitudes and thoughts after asking a whole bunch of local woodworkers. But are our general impressions accurate?

Let's start with a visual comparison. As you can see in the photo, the white paper towel roll is much larger. Once opened, it is obvious that there is a fair amount of air between the layers, and were the roll wrapped as tightly as the blue paper towels, it would be considerably smaller. Actually, when weighed on a very accurate gram scale, the unopened rolls are almost identical in weight… 353 grams for the blue roll and 354 grams for the white roll.

The blue roll contains 43.6 square feet, the white roll contains 70.58 square feet. Therefore, the weight per square foot of the blue towel is 8.1 grams and the white is 5.0 grams. So the blue towel is a heavier weight. I checked the thicknesses of the various towels and found a very wide range within both rolls. I ultimately took over one hundred measurements of both the blue and white towels in one hundred different places along the length of the roll. On average, the white towels were about .40mm thick and the blue towels were, on average, .44mm thick. A small difference, but enough to account for the impression of thickness and partly the weight per square foot difference.

|

Figure 13 - Compare price per square foot to

get around the packaging hype

|

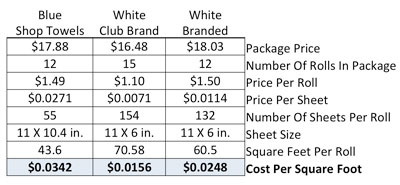

In the chart above is a comparison of prices between paper towels, all from the same wholesale "club" store. It is pretty easy to get lost in the various sizes of sheets, the number of sheets per roll, and the number of rolls per package, so the only meaningful comparison is the price per square foot (highlighted in the chart).

|

Figure 14 - Both blue and white paper towels could be torn

relatively straight and easily in either direction

|

At 3.4 cents per square foot, the blue paper towel is more than double (119% more) the cost of the unbranded wholesale club plain white paper towel at 1.56 cents and 38% more than the branded paper towel. Is it worth the extra cost?

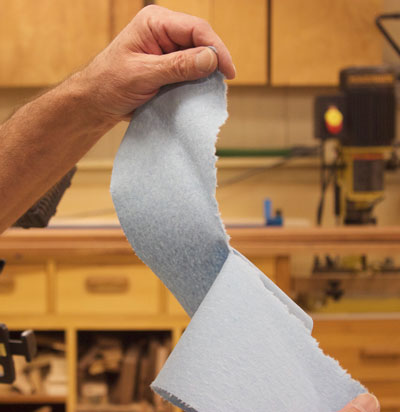

Before conducting a tear test, I checked to see if there is a "bias" to either the blue or white towels… we woodworkers might think of it as "grain direction." You know how this can impact tear strength. Most newspapers tear easily and in a relatively straight line when torn top to bottom, but when we try to tear the paper side-to-side it tears unevenly and with more difficulty. It has to do with the way the fibers are oriented as the paper is manufactured. According to my tear tests, there was no obvious bias to the paper in either direction. To make sure the tests were as fair as possible, I conducted all the strength tests with the paper towels oriented the same way.

|

|

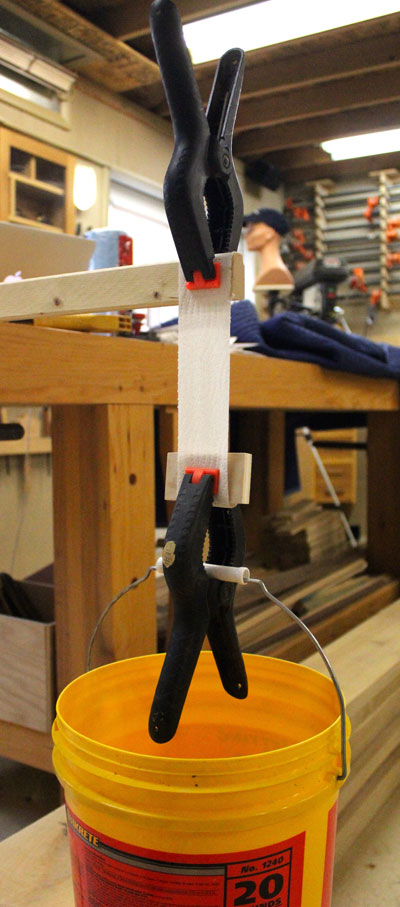

Figure 15 - Strength test set-up

|

I anticipated a difference in sheer strength, and would have placed a wager that the blue towel was significantly stronger. I would have lost that bet. When tested dry, the plain white paper towels averaged breaking at 55 ounces and the blue towels broke, on average, at 46.75 ounces. The blue towels did, however, excel when tested wet. In the wet strength test the blue paper towel broke, on average, at 29.9 ounces, the white paper towels consistently broke at well less than 20 ounces.

|

Figure 16, 17, 18 - Strength test set-up

|

In the accompanying three photographs above you will see first a clean baseline photo of the top of my SawStop extension table. It was cleaned and dusted with a microfiber cloth. I then checked the amount of lint produced by each type of paper towel. I developed a repeatable system for "agitating" the towels precisely the same and then photographed the resulting lint released. The white paper towel produced a veritable "ton" of lint, as expected, but I was surprised how much was produced by the blue paper towel. Less, to be sure, but still quite a bit.

I attempted to develop an abrasion resistance test, but testing repeatability was inconsistent and the results were therefore unreliable. It did appear, although I cannot substantiate it, that the blue paper towel held up a little better, on average, than the white towels.

Using a subtractive technique, I tested the towels for absorbency and found that the blue paper towels do absorb more water per square foot… about 19% more.

Prior to this comparison analysis and testing, I perceived the price differential between blue and white to be much greater. I will still use both types of paper towels in my shop, but given the wet-strength superiority, absorbency, the softness, and relatively less lint, I will not be quite so frugal or judicious in how and when I use the blue paper "shop" towels in the future.

(Page 3 of 4)

Previous Page

1

2

3

4

Next Page

Return to

Wood News

front page