Making Whirligigs Can Be Fun and Addicting

by Ken Radziwanowski

East Windsor, NJ

Click on any picture to see a larger version.

A few months ago, a friend brought over a broken whirligig and asked me if I could

repair it. Since I had never made or even touched one before, I was interested and said

I'd take a look at it. It was one of those double-winged flying ducks that you see on

people's lawns. One of the wings (propeller blades) had come loose from the hub and the

hardware parts were loose and rusted. Fortunately, the repair was simple and after

applying a few dabs of good exterior glue, some touch-up paint and a few new brass

screws, it was better than new. Unfortunately, by doing the repair, I realized how easy

they are to make and so for the past few months now I can't seem to stop building them!

Right after repairing my friend's whirligig, I did some quick research on the internet and

discovered all kinds of whirligig styles and designs. There were photos and plans that

ranged from simple two-blade/one hub propellers to some that had four blades, multiple

hubs and even gears and drive shafts to move funny characters – all powered and driven

by the wind. It didn't take long to realize that the creative choices for someone with

basic woodworking skills (me!) could let their imagination run wild. Since the options

were endless, I started putting pencil to paper.

|

My first personal whirligig was an airplane (seen above) – a standard tried and true design.

Starting with nothing more than a 2' long piece of 1" x 4" pine, a few paint stirrers and

some brass hardware, I cut it, painted it and quickly put it together and placed it on a pole

in the back yard. The wind blew, the tail (rudder) steered the plane into the wind and the

propellers turned. Success! Now motivated to make more, I wanted to get a little more

creative and also finds ways to shorten the building process. So, I went back to the

internet looking for more whirligig ideas and resources.

I quickly discovered that there are various web sites and suppliers –

including Highland Woodworking

- that sell equipment and reference materials for building whirligigs.

Some even offer whirligig hardware and other parts. After completing just a few

projects, I learned that for minimal cost, I can even buy much of the hardware and basic

components "on-line" and that by having them delivered to my door, I can shorten and

improve my construction process. Also, in this way, I can focus and spend more time on

creating fun designs and personalized themes for the whirligig projects that I create as

gifts for family members and friends.

|

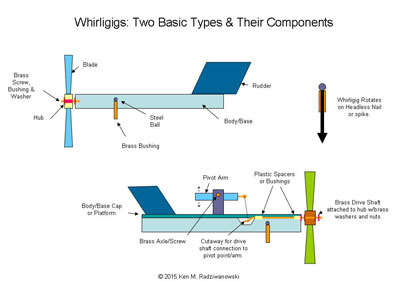

The first several whirligigs were all of simple design. Each had a body made of 1" X 3"

pine or poplar. (See above diagram of basic whirligig parts.) The propellers were

dual blade hubs attached to the body with a brass flathead screw, brass 1/4" bushing and a

brass flat washer. The only design change I made for each of these was that the tail or

rudder was modified to reflect the theme of the item. For example, I used the silhouettes

of a French bulldog, a hummingbird, and a pig as rudders or tails. For one that I made

for my father-in-law, a WWII Navy Vet, I used the silhouette of a destroyer chasing a

submarine. The hub was positioned at the back end so that it appears as the propeller of

the Navy destroyer!

|

|

Navy destroyer whirligig

|

As I gained experience and did more research, I started building whirligigs that had

characters and actions that were also powered by the wind. While I could buy the basic

parts as before, I needed to use a scroll saw to shape the characters. Also, there's a

certain amount of "hit and miss" adjustments you'll need to make to get the mechanisms

to turn and rotate properly. However, the design possibilities are endless. You can

make these moving crafts as simple or as complex as you like. Your only limitation is

your imagination. To determine design themes, I used my other hobbies and the interests

of family members. Since I also enjoy trap shooting, one of my projects involved a

moving trap shooter. Another animated yet simple whirligig design has two children

playing on a seesaw.

|

As shown in the above illustration, the components are simple and construction for the majority

of designs is straightforward. For my first few projects, most of the wood that I needed

was sourced from extra pieces I already had in my workshop. I ordered the brass

hardware, drive shafts and propeller blades from on-line woodworking supply stores. For

the rudder designs, I used craft plywood purchased at a local hobby store – which is

supposed to hold up better when painted and placed outside. And for the paint, I

recommend you do what I did. I visited my local large hardware supply store and

purchased a variety of colors in small trial size containers of exterior satin enamel. They

were available in 7.25 oz plastic containers and are handy, have

screw tops for easy closing, and have covered multiple whirligig projects without creating

any mess or waste.

Once you get started, you're sure to develop a few tricks of your own. I have found that

trimmed down paint stirrers make for good small propeller blades and hard plastic tubing

cut into small pieces can serve as adequate bushings for drive shafts. Before starting to

paint the design and characters, I keep a collection of various artists' brushes and a glass

of water nearby (for cleaning them) and then I'm ready to go. In fact, I have found that

painting each whirligig has actually become one of my more favorite activities in the

process as the colors really bring each design and their different characters to life.

So, if you're lucky enough to have some spare time, have basic woodworking skills, and

want to make whimsical crafts for yourself or as gifts to be enjoyed by others, I

confidently recommend you try making a whirligig, or two. Who knows, there may be a

double-winged duck just waiting to be built in your workshop right now.

You can email Ken at

kenmradz@verizon.net

or take a look at his Whirligig Etsy website at

https://www.etsy.com/shop/KindOutdoors?ref=hdr_shop_menu

Return to

Wood News

front page