by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

This month:

•

Sharpening Your Tools

•

MFAQs (Most Frequently Asked Questions)

•

On The Level – Machinery Set-Up For Un-Level Floors

•

Prime Shop Season Is Almost Here!

Sharpening – A Not-So-Dull Topic!

Click on any picture to see a larger version.

My normal level of disinterest in tool sharpening is epic. Measuring it would take an atomic scale or a tunneling electron microscope… but lately I have been thinking a lot about sharpening and my interest has been rekindled.

|

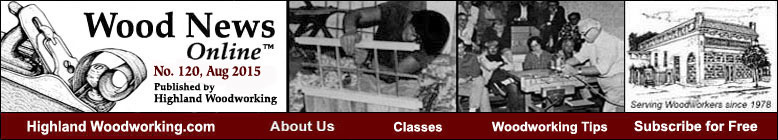

Figure 1 - My basic sharpening set-up...

three water stones and a little water for

spritzing, splashing, and soaking

|

You see, sharpening tools is simply an end-of-day routine for me, no different than sweeping the floor or emptying the dust collector. I do it with no more thought than is required for breathing and no more attention than I would give a soccer game (sorry soccer fans). It is a boring activity, a mindless exercise… time I usually spend thinking about the next day's woodworking project or what to cook for dinner.

In the past fifty years or so I haven't thought much about sharpening, but I have had a few small temporary spikes of interest along the way.

The first was at five years of age. My father told me how the settlers mixed clay and water and sun dried small bricks that were used to hone the edges of axes and knives. I'm pretty sure he made that up, but there was plenty of red clay in East Texas and it gave me a chance to use my Dad's saw and hammer to build a small box in which to pack the clay and form the "brick." I honestly don't remember if I ever got anything very sharp using my homemade sharpening stone, but it kept me busy… and interested… for a few days.

My Dad had a couple of real stones and a can of oil with which he sharpened everything, but I was not allowed to touch those tools in my tender youth. I watched, we talked, I learned, but I never touched.

Another spike of interest occurred after my Grandfather passed away. In his barn there was an old foot-powered grinding wheel. I was twelve then, big for my age, but I still remember that contraption as being quite large. It was one of the few things we took home from my Granddad's house, and for some unknown reason this was a tool I was allowed to use. I could get it going fast enough to throw sparks from axes, hatchets, shovels and hoes. I sharpened everything in sight. Soon, though, my attention faltered and interest was again lost. This might have been about the time I discovered girls… who knows?

Later, in my teens, when I started woodworking in earnest, I didn't give much thought to sharpening tools. Having by then been granted rights to unlimited tool use, I simply followed in Dad's footsteps and robotically used his oilstones. Probably another quarter-century passed before I gave much thought to sharpening again. That was when I finally bought my first set of water stones. It was an easy transition since there was no need to change technique… just splash water on the stone instead of oil… slightly better results with a little less mess. A working system that served me well, the new water stones held my interest for a couple of days then sharpening became, once again, a mundane activity.

Then came what I call my "mid-life crisis" period… from about my mid-forties to my mid-fifties (some crises are over in a flash, mine seem to drag out over long periods of time). Perhaps I had too much disposable income. Perhaps I was simply buying sharpening tools and machines instead of a convertible or in lieu of the de rigueur extramarital activities many mid-life sufferers try. Instead, I flirted with a ton of different sharpening methods. Any electrical gizmo that touted perfect edges without effort tempted me more than any sports car could and I laid out the cash. None of the machines worked very well and none of them gave me a better edge than my water stone method. Thank goodness eBay came roaring onto the scene, or I would have compiled a museum's worth of Johnny-come-lately sharpening machinery as de facto dust collectors.

Over the years I bought better (and more expensive) water stones, but my system never really changed. There was another brief flirtation with the so-called "Scary Sharp" system… I still have a nice hunk of flat marble if anyone wants to pay for the shipping… and I will admit that perhaps the sharpest edge I ever put on any tool was during that period of time. But the ridiculous amount of time I spent attaching, peeling, cleaning, and re-attaching sandpaper, shopping for sandpaper, and frequently tearing an expensive piece of sandpaper with the edge of a tool quickly sent me scampering back to my water stones.

And so it has been for most of my woodworking life… three water stones and a lot of apathy relative to sharpening. Some have asked if I would do a video on sharpening, and I couldn't, for the life of me, think of a reason to do so… it just seemed so, uhh, boring. I sharpen tools subconsciously, robotically… a little like shaving. When you perform your morning ablutions do you spend a lot of time thinking about shaving technique, wondering if there is a better machine for your facial hair, if a different razor might change your life, or a different soap? Probably not. In all likelihood you shave the way you have always shaved and don't give it a lot of deep consideration.

I will acknowledge that a lot of people are challenged, intimidated, frustrated or mystified by tool sharpening. I'm one of the fortunate that is not.

In the midst of all this glorious indifference to sharpening methods and machines, Highland Woodworking asked me to do a video tour of the

Tormek T4 Sharpening System

. It was a little like waking up one morning to find a can of Barbasol in place of my mainstay shaving soap and badger bristle brush. In preparation I read a lot about the Tormek system and found my interest in sharpening suddenly rekindled. Might there truly be a better way? Always up for an experiment, I eagerly undertook the challenge.

|

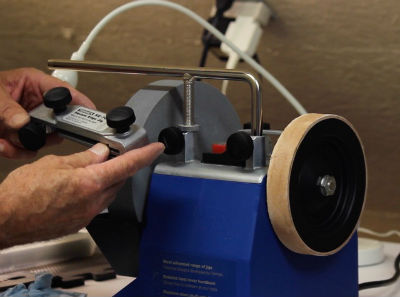

Figure 2 - One view of the Tormek,

including the Square Edge Jig

|

The Tormek T4 Product Tour video will be posted by Highland within a few days of the appearance of this column. You will find the information in the video useful and hopefully entertaining, but video time limitations mean that a lot of information had to be left out. Next month this column will cover many aspects of the Tormek (and sharpening in general) that there was simply not time for in the video. For now though, I want to give you a quick summary… and there is a very good reason I want to do that.

The Tormek is essentially a water-cooled grinding wheel. It turns relatively slowly, so there is no heat build-up and water is not flying around your shop. The single stone can be "re-graded" an unlimited number of times from the equivalent of 220 grit to 1,000 grit and back again, satisfying both shaping and sharpening needs on a single wheel. The other end of the machine sports a leather wheel that when used with the included honing paste will put a mirror polish on sharpened blades. The real magic to the Tormek system is the variety of jigs and tool supports available… there is simply not a blade you can think of that can't be accurately and repeatedly sharpened on the Tormek. I would think the Tormek would be an almost "can't live without" tool for turners, carvers, chair-makers, instrument builders, and others that use a large variety of hand-powered cutting and shaping tools.

For a "regular guy" (like me) that sharpens mostly plane irons and chisels, and does it pretty well by hand, it might be considered a luxury item. But if you are "sharpening challenged" and have never felt you could get a keen edge by hand, it might just be your salvation.

With a price tag of $399, the Tormek T4 is an outstanding alternative to, say, an 8" variable speed Delta bench grinder, currently priced about $165. You say, "But Steve, that's $225 more!" To which I reply, "Just burn one of your fine Japanese chisels on that bargain dry-wheel bench grinder and then tell me how much money you saved!" I won't even mention that with the Tormek, you won't have to worry about that shower of sparks a regular bench grinder produces or that the Tormek can sharpen way more than just woodworking tools.

Like anything, there is a learning curve with the Tormek, but it is not difficult (I successfully sharpened my first plane iron within 45 minutes of opening the box) and once learned, each tool set-up is absolutely repeatable. So if you have difficulty (or think you have difficulty) getting the right touch and "feel" for hand sharpening and want reliable repeatable results, this is a great solution.

So why did I give you a sneak peek of the full review? If you have ever thought about investing in a Tormek, it will be tempting to "pull the trigger" this month because of a promotion that allows you to get the

Hand Tool Kit

at a special price. So rather than wait until next month's Wood News Online and possibly miss the sale price, I thought I should give you a sort of "bottom line" assessment. The Tormek machine is extremely well made, the instruction manual is outstanding, and the edges you produce will rival anything even the best hand-sharpener can do with water stones. You will need to buy the

Square Edge Jig

accessory ($60) for sharpening chisels and plane irons with the T4 (it's included with the

T7 Model

). And if you do pull the trigger and make the purchase this month, do yourself a HUGE favor and splurge $57 for the

Rotational Base

accessory (works with either machine)… you will thank me for that suggestion.

Next month we will go into deeper detail on sharpening in general, the Tormek system, some idiosyncrasies I have encountered and the easy workarounds I've devised, and, most importantly, some tips to get the most out of this versatile machine.

(Page 1 of 4)

1

2

3

4

Next Page

Return to

Wood News

front page