by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 3)

Previous Page

1

2

3

Next Page

Saw Mills & Board Descriptions

Click on any picture to see a larger version.

Before getting into the how's and why's of lumber production and how to find and buy the best, we need to clear up some confusing terminology.

One of the most misused words in woodworking is "quarter-sawn." Second in misuse, but not by much, is the term "rift-sawn." So let's start by first deciding what we want to describe when we use these terms. Are we describing the end result… the wood itself… or are we describing the way the log was cut into boards at the sawmill?

|

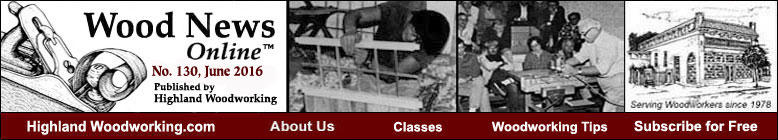

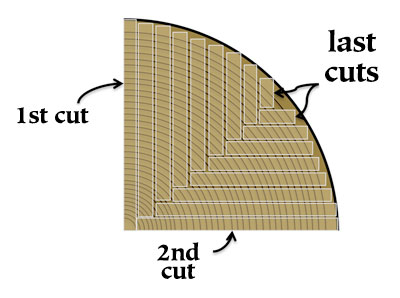

Figure 6 - The first step in "quarter-sawing"

a log... cut it in half...

|

|

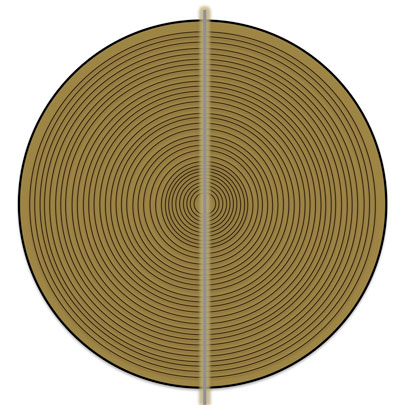

Figure 7 - The halved log is then laid flat

and cut in half again...

|

|

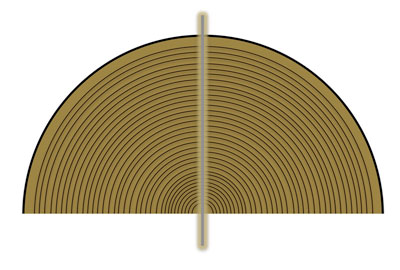

Figure 8 - The "quarter-log" is then cut

into boards...

|

|

Figure 9 - After each cut, the quarter-log is

turned

end-for-end and positioned with its

"last cut face"

down for the next slice

|

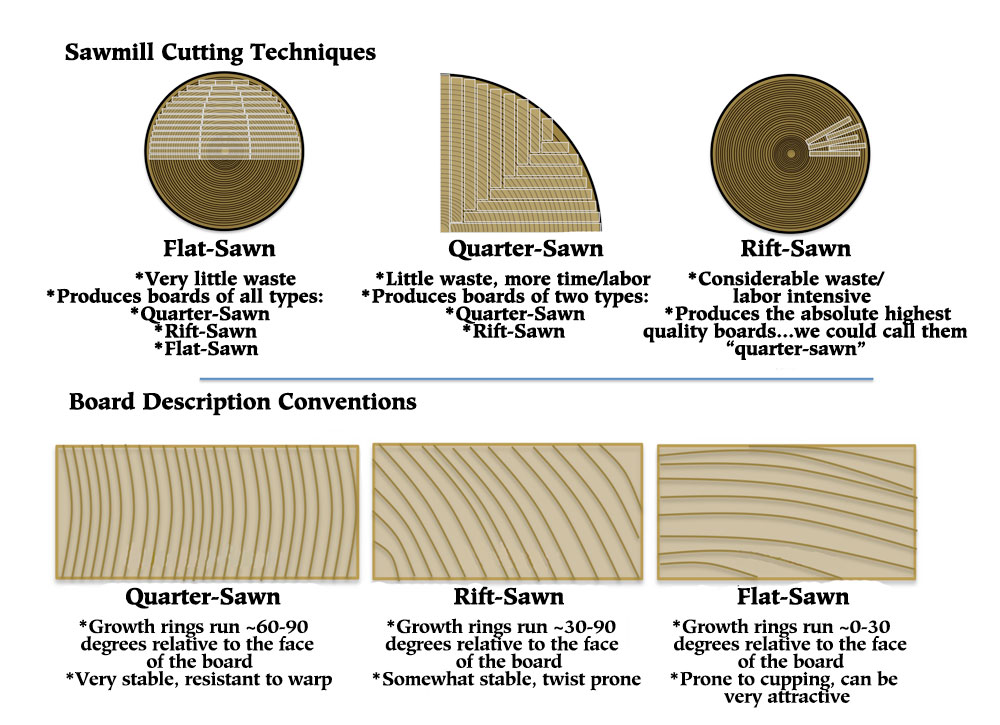

When asked, most woodworkers will describe quarter-sawn lumber as wood that has vertical (or near vertical) growth rings running from top to bottom of a board when viewed from the end. Let's examine whether that is a correct description or not.

Quarter-sawn actually describes a technique for cutting wood from a log that involves first "quartering" the log, then cutting slices from each quarter-log piece. The log is first cut in half, the half-log is then laid on its flat face and cut in half again. The resulting quarter-log is then sliced. After the first slice the log is turned end-for-end and tipped over onto its just-cut face and a second slice is made. Then the log is turned and tipped again and the process repeats until the resulting pieces are too small to sell.

If you look closely at the boards labeled "1st cut" and "2nd cut" (see Figure 9), we would probably all agree that the grain pattern is what we expect to see in "quarter-sawn" lumber. But by the time we get to those boards nearing what are labeled the "last cuts" the tree rings are not running at 90 degrees to the face of the board, but at some angle much less.

In practice, mills typically refer to any lumber wherein the growth rings range from 60 degrees to 90 degrees as "quarter-sawn." Some are even a little "loose" with this definition, calling all lumber that has been sawn using the quarter-sawing process "quarter-sawn." And in truth, if we are speaking of sawing technique, it is.

|

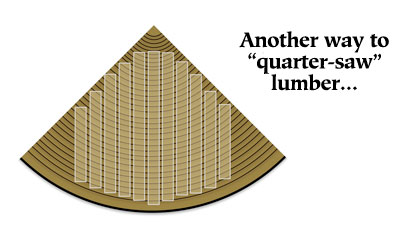

Figure 10 - Another method of "quarter-

sawing" but are all

these boards functionally

"quarter-sawn?"

|

Given the definition of tree rings running at 60 degrees to 90 degrees from the face of a board, it follows that "rift-sawn" lumber is often defined as tree rings running at 30 degrees to 60 degrees from the board's face. This is relatively handy nomenclature, and I use it, but like "quarter-sawn" the term is misused. Actually, it is completely wrong. But the terminology has stuck because we all use it. Rift-sawing is actually a very expensive method of sawing a log that yields the finest lumber of all. As a result, unless you do it yourself, you will probably never see any true "rift-sawn" wood.

|

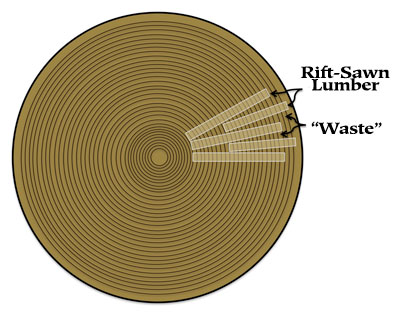

Figure 11 - "Rift-sawn" lumber is the most dimensionally

stable and beautiful of all techniques, but it is expensive

and

"wasteful" in today's vernacular

|

To "rift-saw" logs, cuts are made radially from the center, yielding only boards with almost perfectly vertical grain when viewed from the end. As the illustration indicates (see Figure 11), there is a ton of "waste." Remember, waste is a contemporary concept and definition… craftspeople of yesteryear would look at the "waste" wedges between cuts and see instead "siding" or "shim stock," or even firewood… but not "waste." Many of the wonderful antique pieces of furniture that have survived for us to enjoy today utilized lumber that was "rift-sawn."

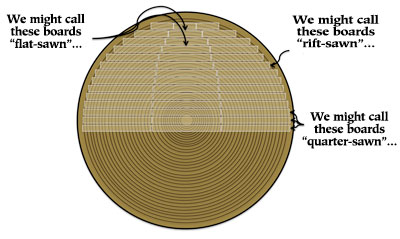

If "quarter-sawn" is used to describe a piece of wood instead of the method of cutting that wood, it is usually defined as growth rings running at 60 degrees to 90 degrees. Likewise, if we describe a board as "rift-sawn" it is usually defined as growth rings at 30 degrees to 60 degrees from the lumber face. Everything else is considered "flat sawn." In reality, as a method of producing lumber, almost all logs today are "flat-sawn." In fact, if you buy a chainsaw or band saw lumber mill, you will likely "flat-saw" all your lumber. The definition, simply, is to saw flat boards one at a time, from the top down (or from one side of the log to the other), without flipping or turning the log and with minimal "waste."

|

Figure 12 - Example of "flat sawing" --- the most

cost-effective,

least wasteful, and therefore most

common way of sawing

boards from logs

|

As you can see from the illustration (see Figure 12), even this most cost-effective way of sawing lumber yields a few boards we might refer to as "quarter-sawn," a few we might call "rift sawn" and a bunch of boards we refer to as "flat-sawn" --- even though the whole log was "flat-sawn."

Confused? Just remember, if you are describing a piece of wood, the terms "quarter-sawn," "rift-sawn," and "flat-sawn" are reasonably descriptive and most people will understand what you mean… but those names have nothing to do with how the boards were sawn from the log.

For the purposes of this article, and for simplicity, we will use the somewhat now-common-practice way to refer to lumber. "Quarter-sawn" will refer to boards that have vertical (or near vertical) growth rings when the board is positioned horizontally and viewed from the end. Growth rings that run at an angle of roughly 30 – 60 degrees relative to the wide flat horizontal edge of our board will be called "rift-sawn" and everything else will be called "flat-sawn."

When looking at the face of a board, what we call "quarter-sawn" will have relatively evenly spaced grain patterns that run fairly straight and true down the length of the board. What we call "rift-sawn" boards will have relatively straight grain, but the grain patterns will appear to have more separation and may even exhibit some "cathedral" grain appearance. When we refer to "flat sawn" lumber, the board's face will be dominated by "cathedral" grain. More about that, including examples, in Part 2 of "All About Wood Movement."

|

|

Figure 13 - Print this photo out and put it up in your workshop if you would

like a reminder

|

Please note that the illustrations I made for this article are just… illustrations. I made perfect circles to represent growth rings and imagined a perfectly round log. We all know that no slice of any log will be perfectly round, its growth rings will not be perfectly round or evenly spaced, and importantly, that no two slices of the same log taken more than a few inches apart will look exactly alike. Like us humans, trees share some common DNA, but each is as different and unique as you and me. Some of the differences are genetic, some are environmentally caused. In Part 2 (appearing in Wood News Online the first week of August) we will look at boards in a holistic sense, from end to end, and look at how the changes along the length of a board can, and usually do, affect movement and stability. We will also look at how to "read" and predict wood movement, some ways to minimize adverse movement or utilize it to our advantage, and how to best build from wood that is not the best.

(Page 2 of 3)

Previous Page

1

2

3

Next Page

Return to

Wood News

front page