Sanding A Sculptured Rocker

(or, "Daddy, are we there yet?")

by Charles Brock

Columbus, Georgia

"If you are a fine woodworker, do you have to like sanding?"

I had a student ask me this salient

question yesterday. He was building a Krenov-style table at my school and was hand sanding the

gentle curves of the table's legs. The answer for me is this – I do not like sanding per se, but I

do love the results of my efforts.

Final sanding of a rocker is a marathon, not a sprint! Sanding a rocker takes a lot more time than

the initial roughing out. I can build a rocker in a couple of days. Sanding is something different.

I used to do it by hand, but then I found some time savings by using an angle type drill with a 2" disk

and an interface pad. The drill was a good one but did not last long under this kind of punishment. The disk would

also sometimes fly off the interface pad with just a little speed. Then I moved to a pneumatic sander with

another 2-inch random orbit pattern. Speed was hard to control and there was no dust pick-up (except via

my nose and a dust-pan).

Because of all of the variations in surfaces and the problems with sanding the seat contours and

under the arms, I can't use a 5" random orbit power sander because it's too big, bulky and just

plain too hard to work with on this kind of project.

It takes some true grit to remove the rasp marks and scratches made by 24 grit paper when using my

Festool angle grinder

. First sanding at about 40 to 60 grit is still in the realm of shaping; you must work

out all the highs and lows in a surface or discrepancies in a hard or soft line, and reconcile one

part or side to the other for the sake of symmetry. I consider myself still shaping until I get to

100 grit sandpaper. Just establishing a consistent scratch pattern is the next order of

business.

As for scraping, I do continue to scrape all the way up to 100 grit in the shaping mode. After

establishing the overall shape, I usually will lightly scrape the entire piece.

How long is the journey and how many stops do we have to make? How fast can we do it?

Sanding a

rocking chair is more about quality than quantity. You have to sand with each grit until you have:

1. Established a consistent scratch pattern all over the piece or area.

2. Removed all

deviations or exceptions to the surface you are preparing.

3. Softened all hard or knife edged

lines to the touch.

You must utilize all the grits once you start. (24, 40, 60, 80, 100, 120, 150,

180, 220, 320, 400, then the 3M pads (red, gray, white) taking it to 1000 grit (if you are sanding a

ring-porous wood like walnut). Do not skip around. It's important to know what grit to

start with and when to stop. I start with the most effective grit that accomplishes the above. It also

has to be the finest grit that will do the job. You cannot effectively sand a project

like this with 24 grit scratches all over it using 100 grit paper! So you must start aggressively

with at least 40 or 60 grit paper by hand or with power. After that I usually use the higher grits like 180+

to provide softening.

Well Daddy, are we gonna walk all the way (sanding by hand) or ride in a car (use a power sander)?

There are many parts and places on the rocker where you really need to sand by hand.

You can get a feel for the wood and its smoothness, how much pressure is necessary and just get

intimately acquainted where the rubber meets the road.

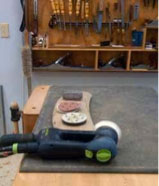

Just recently I started using a

Festool RO-90 Rotex Sander

. It uses a 3" disk and an optional interface sponge pad so that it does

a great job of making constant contact with the contoured surfaces without removing the lines that I

have worker so hard to make. The detail that remains is very crisp.

Just recently I started using a

Festool RO-90 Rotex Sander

. It uses a 3" disk and an optional interface sponge pad so that it does

a great job of making constant contact with the contoured surfaces without removing the lines that I

have worker so hard to make. The detail that remains is very crisp.

After roughing out the chair and

shaping it with a collection of rasps, both powered and unpowered, I can start with usually about 40 grit

and work my way up the schedule. This saves time and produces outstanding results. The sander is

easy to hold and move around the chair. I like to sand as much as possible before I start gluing up

the chair. I finish by gluing, fairing in the parts and sanding the transitions.

As with most Festool

products,

dust extraction

on the RO-90 is easy and excellent.

The sander works in two disk modes. Rotex is fast and

aggressive, the other random orbit. After 40 grit or 60 grit, I seldom use the Rotex mode. They also

have a red and gray 3M pad equivalent that makes burnishing very easy. Then I go over everything

with a white 3M pad by hand. By now it almost looks like I have a very slight coat of finish on it and

it will tell me what I missed. Yes the blemishes just jump out. To remove them, back up only as much as is

necessary grit-wise to remove them.

Sanding stars, flap wheels, inflated sanding domes, drums and such can all be used to help move the

sanding down the road.

Now, does a fine woodworker have to like to sand? The answer is .............. NO!!!!!!!!

Chuck can be reached by email at

rocknchairman@gmail.com

Visit his Sculptured Rocker website at

charlesbrockchairmaker.com

.

Return to

Wood News

front page