by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

End-Of-Workday Project Parts Storage

Click on any picture to see a larger version.

Several woodworkers recently asked if there was a "best practice" for what to do with project parts, pieces and "stuff" when leaving the shop at the end of the day. The answer is emphatically "yes," but the answer may be different depending on whether you are closing up shop for the night, for the week, or longer. Weekend warriors particularly require a strategy for caring for their project parts and pieces.

Long-time readers know I am a proponent of adapting 5S/Lean manufacturing principles to the shop, and two of my mantras are "clean as you go" and "put things back in place." Getting in the habit of doing these two simple things will make you more efficient and significantly reduce the time necessary to clean your shop. It's no different with project parts, half-finished joinery, and partially assembled projects. Organized storage of these "works in progress" is critical.

Every woodworker and every woodworking project will require different short-term storage strategies, but here are a few things that are universal:

-

Label everything. A week from now (or even tomorrow morning) you may not remember which boards were the fronts and backs of drawers and which were the sides. It may be difficult to remember the order and layout of boards intended for a panel glue-up or what pieces were intended for aprons and which for stretchers. Chalk is great. It wipes off easily, shows well on most woods, and will not interfere with finishing later on.

|

Figure 8 - Labeling parts assures a

"fast start" when you return to the shop

|

-

Stack freshly milled parts carefully. When initially milling rough stock I often let parts "rest" overnight or longer on purpose so that if they feel inclined to bend, bow or twist, they can do it now. Depending on the moisture content of the wood and the humidity in the shop, more often than not I stack the boards with stickers between and separating the pieces to allow air movement. I usually put a little weight on top of the stack(s). Tomorrow or next week the boards usually have experienced some minor movement that can be corrected in the final milling process.

|

Figure 9 - Partly milled parts can "rest"

and relax before final milling

|

-

Store "project-ready" parts even more carefully. When the tenons are cut, the dovetails are done, or the miters are perfected, but you are not quite ready to glue up the whole project, it may be helpful to stack the parts and wrap them together tightly with so-called "plastic twine." Essentially just narrow rolls of shrink-wrap, this stuff is great for tightly binding parts together. Wrapping the parts will minimize movement, protect the parts, and keep everything together until you are ready for your next "shop day."

|

Figure 10 - Plastic shrink wrap is an excellent way to store and

protect project parts that you might have to leave for awhile

|

-

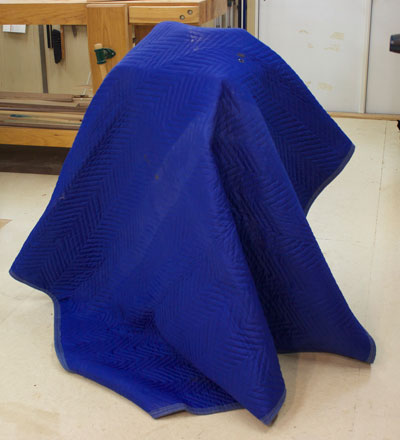

Protect some woods from light. All wood changes color slightly with exposure to light, but some darken noticeably and rather quickly. If you will be out of the shop for a while, you might be distressed to see light and dark areas on that beautiful cherry you milled a few weeks ago. I once left some cherry boards haphazardly arrayed on a workbench, and a few days later, each board had lighter colored stripes where other boards had laid across, shading the light. Stack the boards and throw a drop cloth or blanket over the batch to avoid selective or spotty darkening.

-

Protect partial assemblies. Stuff happens, but it is particularly distressing when it happens to the bottom half of that chair you are building, that partially assemble hutch, or the bench without the back attached. If I had a nickel for every time I have nicked, dented, or otherwise damaged a partial assembly I would have, well, a whole lot of nickels. The best thing I have found for protecting partially built projects is moving blankets. They are fairly inexpensive and afford a lot of protection.

|

Figure 11 - A moving blanket offers protection to this small

chest currently under construction in my shop

|

-

Lock in machinery settings. If you are forced to quit work for the day right in the middle of cutting rabbets, milling decorative edges, ripping stock to width, or planing to thickness, lock in the machine settings and throw a moving blanket or machine cover over the equipment. It is less likely to get bumped out of adjustment and the cover will serve as a visual reminder of exactly what process step you were in.

|

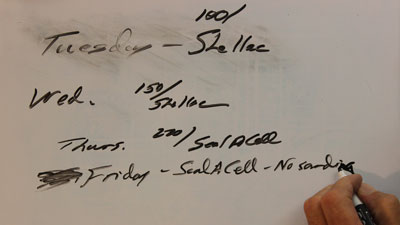

Figure 12 - With multiple projects I can't always remember

what finishing step is next. Notes on a wipe-off board

help me keep track.

|

-

Finishing, particularly for weekend warriors, requires special strategies. You may not remember next week or next month whether you have put on three coats or two, whether you last sanded with 120 grit or 180, if the top has had three coats and the sides just two, or was it the other way 'round? The easy thing here is to just keep notes. My wipe-off marker board is ideal, a notebook will work, too.

The key to all of this end-of-day storage strategy is two-fold. Of course it is common sense to protect wood and project parts, but it is also important to save time and be more efficient. When things are properly stowed at day's end, you can jump right back into the project at your earliest next opportunity without having to stand around, scratching your head and wondering, "Now what was I working on last?"

(Page 2 of 4)

Previous Page

1

2

3

4

Next Page

Return to

Wood News

front page

|

|