by Steven D. Johnson

by Steven D. Johnson

Racine, Wisconsin

This month:

•

Tale Of The Tape(s)

•

Construction Of The 5S Compliant Shop Wall Cabinet

Tale Of The Tape(s)

Click on any picture to see a larger version.

Want to get some interesting comments or questions from workshop guests? Try filling a corner with dozens and dozens of boards dappled with small pieces of tape, each with an indecipherable code number. For the past couple of months I have been conducting long-term tests on packing tape, conventional masking tape, and so-called painter's tape. My guests now think I am crazy or obsessed. Actually, they may have had those thoughts before.

|

|

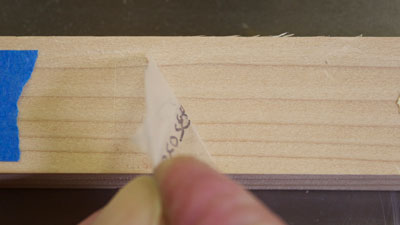

Figure 1 - One of dozens of sample boards from my long-term testing

|

To assure there were no environmental influences, the sample boards were all stacked side-by-side in a part of the shop not exposed to direct sunlight and where I know the temperature to be fairly stable, about 68-degrees Fahrenheit.

Each sample was given a code number that indicated the date and time it was adhered to the wood, the manufacturer, and other data I thought might be important. The same species of wood was used for all tests.

On a predetermined date, I removed each of the pieces of tape. This represented "adherence" times ranging from one day to four weeks. I compared how hard the tape was to remove, how much residue was left behind, and the amount of wood fibers attached to the tape after removal.

Concurrent with these tests, I also subjected tape samples to higher temperatures, lower temperatures, and humidity variations. I also compared some rolls of tape that have been in my "tape storage box" for awhile to judge aging characteristics. I tested each tape with different types of pens and pencils to see whether writing on the tape was feasible.

Because I don't have sophisticated test instruments, my findings are observational, somewhat subjective, and should be read as such. But I was very careful and consistent in the procedures I used.

Residue

All tapes leave some residue, despite the claims. As outlined last month, when adhesion (tape sticking to a surface) surpasses cohesion (adhesive sticking to itself), residue is left behind. This is actually pretty easy to see. Run an adhesive lint roller across a clean sheet of glass and the residue will show… faintly… but it will show.

As a side note, my cats loved being "rolled" with a lint roller… and I didn't mind, since any hair the lint roller picked up was less hair on my chair cushions. When I offhandedly mentioned to the veterinarian that my cats liked the lint roller, she advised me to stop. She said the adhesive residue would get on their hair, and as they groomed themselves, they would be ingesting the adhesive.

|

|

Figure 2 - "Painter's Tape" left the least residue,

hardly visible to the naked eye

|

|

|

Figure 3 - Plain masking tape left a lot of residue

when removed

|

|

|

Figure 4 - Like "painter's tape" heavy-duty packaging tape

left almost no visible residue

|

The amount of adhesive left behind varies significantly among types of tape and the length of time the tape is left in place. As you might suspect, so-called "painter's tape" leaves the least, even when it is left on much longer than the manufacturer's recommended time limit. Interestingly, old-fashioned masking tape (the tannish-brown stuff) leaves the most adhesive behind. What did we do before there was "painter's tape?" Clear packing tape, with the strongest adhesive bond of the types of tape I tested, also left almost no residue, a surprise I had not expected.

|

|

Figure 5 - Photo shows how even "invisible" residue from

painter's tape grabbed the ultra-light flour particles

and held them tightly"

|

Want to see some tape residue that is otherwise invisible to the naked eye? Try my test. After peeling off pieces of tape, I sifted a small amount of baking flour onto the wood, turned the board upside down and beat it against the cabinet to dislodge any loose flour, then examined the wood to see if any "invisible" adhesive was grabbing the flour particles. As you can see, all tapes left residue.

Fiber Pick-Up

|

|

Figure 6 - Wood fibers lifted when tape peeled away

|

All tapes, when peeled off of raw wood, also removed some wood fibers. The blue painter's tape was surprisingly worse than the rest, but the aforementioned science explains it. Since the cohesion/adhesion ratio is higher compared to other tapes, the tendency is to leave behind less residue… but this cohesion also means that as the tape is peeled off, the adhesive has to "decide" where to go. It wants to stay with the tape, due to its high cohesion, so for the most part, it does… and the wood fibers go with the adhesive when it is peeled away. Clear as mud? Not to worry, the picture explains it all.

The ability of a tape's adhesive to pick up fibers and other detritus explains why tape can only be peeled and reapplied a couple of times before it is useless. When enough "stuff" gets imbedded in the adhesive, it simply won't re-stick to another surface very well.

Can I Write on the Tape?

The answer is "maybe." It depends on what you write with. As you can see in the photo, I first tested a ballpoint pen. It writes okay on blue painter's tape and regular masking tape, but hardly left a mark on the packing tape. One note here… a ballpoint pen tends to "telegraph" through the tape to the wood below. Not the ink, but the actual pressure of the pen tip leaves a visible outline below.

The second column tests were done with a No. 2 pencil. Visible on the two masking tapes, but for the same "telegraphing" reasons outlined above, I would not use a pencil to write on tape already applied to a wood surface.

In columns three and four I tested a Sharpie ultra fine point pen. In column three I simply wrote the word "test." In column four I wrote "test" and within 2 seconds wiped my finger across the ink. All three tapes performed reasonably well in both these tests. Column five and six are tests performed with a Sharpie "fine point"--- doesn't look too fine, does it? In column six you can see that all three failed the smudge test, the packing tape performing the worst of the three.

I didn't expect much, and was not surprised, when I tried chalk in column seven. I was a little surprised that a lumber crayon in column eight did not show on the packing tape at all.

If you need to write on tape for any reason, get a Sharpie ultra fine tip pen. It dries quickly, does not bleed through, and shows up well.

Does Tape Have a Shelf Life?

|

|

Figure 8 - Old tape will not come off the roll cleanly and

tears easily

|

I tested a roll of blue painter's tape and a roll of plain masking tape that had been stored in a plastic container for almost a year, and both faired pretty poorly. The plain masking tape would hardly unroll. It was stuck to its own backing so strongly that the tape kept tearing and would not come off the roll in a continuous strip. The blue painter's tape unrolled smoothly enough, but left a considerable amount of adhesive on the wood surface after only a day.

At least in my limited experience, tape most definitely has a finite shelf life. In fact, when I retrieved those old rolls of tape from their sealed plastic storage box and realized they were, for all intents and purposes, unusable, I tested all the other tape in that box and had to dispose of almost all of it. Only a six-month old roll of packing tape was still okay. One roll of electrical tape and a roll of red duct tape (why did I buy that?) were marginal but still usable.

The adhesive in old tape flows deeper and deeper into the microscopic nooks and crannies of the release layer making it almost impossible to unroll a piece without tearing it (see photo). The next time you see that mega package of tape at a special price, think about how fast you will use all that extra tape. In fact, if you are not going to use tape within six months or so of purchase, I would say don't buy it. You may wind up throwing it out with the trash (along with your cash).

Does Temperature Affect Tape?

Temperature, both in storage and in use, has a profound affect on tape. At higher temperatures the adhesive becomes more viscous and flows into microscopic irregularities on surfaces more easily. This can cause tape to stick to its own release layer and/or leave more residue behind on the surfaces to which it is applied. If you want to experiment with this, apply two pieces of tape to a surface then hit one with a hair dryer for ten seconds or so. It is amazing how much the tape changes.

The Bottom Line

A number of new brands have appeared on the market in the last couple of years but there is not much real difference, at least for woodworkers, between the different brands or grades of painter's tapes. I could identify no discernible difference in any of them. A lot of hyped-up marketing language adorns the packaging; "Multi-Surface," "14-Day," "Professional Use," "Delicate Surface," and "Contractor Grade" are just a few examples. It also seems that manufacturing masking tape in garish fruit colors (fuchsia, lime, tangerine, etc.) is trendy now, too. "Why?" seems a perfectly plausible question.

There is, however, a pretty big difference between painter's tape and old-fashioned masking tape. There is also a pretty big price difference. The same width and length roll of blue painter's tape costs over 2.5-times that of old-fashioned tan masking tape.

Stores frequently have multi-roll packages of tape for sale at a lower per-roll price. Unless you are a volume user, buy only what you can reasonably expect to use in six months or so. You will probably save money in the long run not having to throw out spoiled tape.

Packing tape is a specialty item. If you do a lot of tapered legs or other angled cuts and need to tape pieces back on for stability during the next operation, packing tape is a good choice. But be advised that packing tape will tear off a significant amount of wood fiber when it is removed, particularly on sharp wood corners.

Store tape in a spot that is cool and gets no direct sunlight. This will likely help extend the usable life of the tape. If you feel compelled to write on tape, get a Sharpie or other brand of indelible fast-drying ink pen. Test it in an inconspicuous spot to make sure that the ink is not bleeding through the tape and that it is drying quickly enough that wet ink does not inadvertently transfer to one of your work pieces.

No matter what, there is going to be some adhesive residue left behind on bare wood. I tried sanding to see how well it removed the sticky stuff, and a very light sanding did nothing but press the adhesive deeper into the wood fibers and clog my sandpaper. A lint-free cloth moistened with mineral spirits whisks the adhesive away in a flash. So even if you don't see any adhesive, be safe and wipe bare wood surfaces with a touch of mineral spirits before sanding and finishing.

(Page 1 of 2)

1

2

Next Page

Return to

Wood News

front page