|

|

|

|

The Down to Earth Woodworker

By Steven D. Johnson

Racine, Wisconsin

|

|

This Month's Column:

•

A Wet, Wet Summer

•

The Right Tools Do Make A Difference

•

Rust --- Hand Planes --- The Right Tools --- What Else?

A Wet, Wet Summer

Click on any picture to see a larger version.

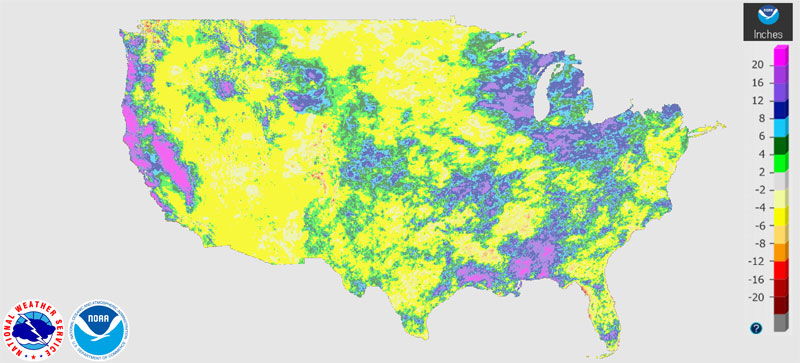

After several years of woodworking, remodeling, woodworking, room additions, woodworking, and more remodeling, the inside of my house is pretty much okay… there is still a list of projects, but all can wait 'til winter. This was to be the summer that the long list of outdoor projects was finally tackled. But it is hard, if not impossible, to do certain types of work during torrential rainfalls, and we have had a lot of them. In fact, we are some 16-inches above normal rainfall so far this year.

|

Figure 1 - That purple-ish splotch to the left of Lake Michigan is

where my shop is located, and the map colors indicate we are some

16-inches above normal for rainfall this year

|

There are, of course, great swaths of the U.S. that are below average for year-to-date rainfall, and I feel your pain, too. I suppose everyone would like a predictable pattern of weather, year-in and year-out, but it just doesn't work that way. I remember droughts as a boy when our pond dried up and we had to dramatically reduce our cattle herd because there simply was not enough water for them to drink. I remember, too, the "wet years" when that same pond overflowed its banks and the cows slogged knee-deep in mud. We dealt with the wild swings in rainfall as a matter of course.

This year I am dealing, as a matter of course, with extremely high humidity in my woodshop. Normal winter humidity in my shop hovers around 25 – 30% and normal summer humidity is about 35 – 40%. Manageable. This year my shop humidity has averaged 56%, often hitting as much as 70%. For the first time since building this shop, I had to buy and run a dehumidifier… just what I needed, one more thing taking up precious shop space, driving up my electric bill, and making unwanted noise!

Based on the past five years, I think (and sincerely hope) that the dehumidifier is a temporary "fix" to a transient and unusual weather year. I did not bother to provide a drain line from the dehumidifier and simply empty the water collection bucket when it gets full. Lately, that has been about three times every twenty-four hours. In addition to that, I have been employing every rust-preventive measure I know to all my equipment.

|

Figure 2 - The last thing I needed... something else taking up precious

shop space... but the de-humidifier has been critical this year

|

For cast iron machine surfaces, I have been applying

Boeshield T-9

protectant slavishly. I've used more of the stuff in the past two months than in the prior five years here. So far, it is working great, but when you use a tool, it wears away quickly, so where I might have given a spritz to my jointer bed once a week or so before, now it gets sprayed and wiped down daily. Same goes for my

SawStop Tablesaw

, my planer bed, the bandsaw, and the infeed and outfeed tables of my

SuperMax Drum Sander

. I keep a rag and a bottle of

Camellia Oil

on my workbench, and after using a chisel, a plane, or even a screwdriver, the metal parts get wiped down with a few drops.

The humidity caused something to swell and the primary door to my shop would not latch closed. There was probably a more elegant "fix" for this, but in a moment of frustration, I grabbed a

Dremel Tool

and a grinding bit and enlarged the strike plate to allow the door to latch closed. I noticed that the chuck on the Dremel, which gets used all of maybe once per year and otherwise stays put in its little formed plastic case on a shelf upstairs, had rusted. That's not the end of the world for me, but I did spritz it with a bit of oil before I put it away, and realized then just exactly how invasive and destructive humidity can be.

|

Figure 3 -

Zerust Drawer Liners

under a plane in one of my storage cabinets

– this really cuts down on rust!

|

Finding that "hidden" rust freaked me out a little, so one rainy afternoon I dug deep into every drawer, cabinet, nook, and cranny in my shop. Spare blades and bits all got a wipe down with either Camellia Oil or T-9. I threw some desiccant packs into my containers of Festool Dominos and replaced all the

Zerust Drawer Liners

in all the cabinets and drawers that hold metal tools.

Getting into a "tizzy" when rust shows up is poor planning, reactionary, and a little like "closing the barn door after all the horses are gone." It was virtually inevitable I would forget something, and I did. My

Aluminum Bar Clamps

and my Bessey Cabinet Clamps were all fine, but my

Jorgenson handscrew clamps

all developed rather severe corrosion. I took them outside between rainstorms, laid them all out in the driveway, and sprayed them down with

Boeshield Rust-Free

, wiped them down, then sprayed them with T-9. I doubt they will ever be the same, though.

After a particularly bad series of storms that got our geographic area into the national news, a lot of people had flooded basements. I never knew I had so many distant relatives and friends in the area, and I went from house to house with a portable pump and an old shop vacuum set up to remove water. Among the first of the panic calls I also got my dehumidifier to help dry out a nicely finished basement carpet. I thought they might need it for a few days, but it has turned into a couple of weeks now, so I gave up on ever getting it back and bought another dehumidifier today. Oh well, that new tool I had my eye on will just have to wait a bit, I guess.

All this dampness has taught me one very important lesson… be prepared, be anticipatory, and be proactive. Even if the weather returns to "normal" next year, I will continue to treat all my tools as if high humidity is right around the corner… it might be. Better to be prepared!

(Page 1 of 3)

1

2

3

Next Page

Steven Johnson is retired from an almost 30-year career selling medical equipment and supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis (although he says home improvement projects and furniture building have been hobbies for most of his adult life). Steven can be reached directly via email at

sjohnson@downtoearthwoodworking.com

Return to the

Wood News Online

front page

|

|

|

|

|