|

|

|

|

The Down to Earth Woodworker

By Steven D. Johnson

Racine, Wisconsin

|

|

Previous Page

1

2

3

Roller Stands / Portable Work Supports

Click on any picture to see a larger version.

I loathe roller stands. I'll get that out of the way right off. I use them, but I detest them. I have had yellow ones, red ones, black and gray ones, and all roller stands and portable work supports are flimsy, flawed, and potentially dangerous. Sometimes, though, you must use them, and in a pinch, they are a "make do" solution to handling long work pieces in the shop and on job sites. Still, they are generally more trouble than they're worth.

Here is just a sampling of what is wrong with portable work supports:

-

Height adjustment is "iffy." With all these stands you must hold up the weight of the roller/head assembly while tightening a hand crank screw onto a metal shaft. The adjustment is "coarse" at best, and everyone has had the experience of fiddling to get the height "just right" then watching them slip when in use.

-

The units are usually made to fold up when not in use, but too often fold up when in use.

-

Front-to-back (direction of travel) stability is merely "okay," but side-to-side stability is awful. If you haven't had one of these stands fall over under the off-center weight of a big piece of wood, you haven't used these stands very much. It is a common problem.

-

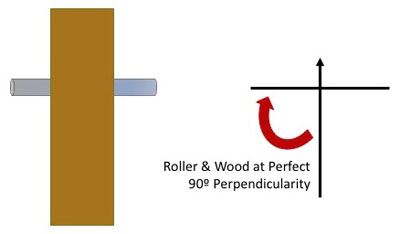

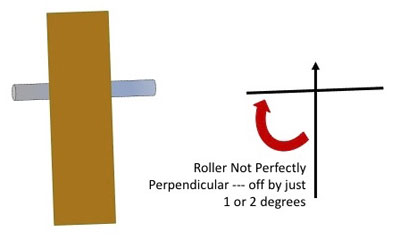

The roller must be at a perfect 90-degrees (perpendicular) to the direction of wood travel, or the roller will tend to "pull" or "push" the work piece in a direction you do not want it to go (see Figures 7 and 8 below). This is the potentially dangerous part when you are using a roller stand to support a large piece of wood at the table saw or band saw, and at the very least, leads to inaccuracies when cutting.

-

Leveling a roller stand is just an awful experience, and if it is not level, the wood you are sliding over the roller will wander off course (see Flaw Number 4 again).

-

Out of the half-dozen or so different models of roller stands I have owned, none would extend high enough, or extend high enough with any degree of stability, to be of much use at my band saw… a place where supplemental support is often necessary.

|

Figure 3 - Otis Campbell was often "tipsy" on

the Andy Griffith Show, but this thing is beyond

"tipsy." Super lightweight, flimsy."

|

|

Figure 4 - A little better, but not much. If the

angled leg faces the same way as the

direction of travel for the wood, this

"sort of" works. No way to level this on an

uneven floor! I have had 4 of these, all of them

eventually broke where the lever tightens

against the leg.

|

|

Figure 5 - Better, but still problematic.

Support mounts for the rollers are too high,

meaning work cannot overlap the sides of the

roller. The legs are a trip hazard and the sharp

metal edges are real ankle-killers!

|

Ask yourself this simple question: In your shop, would you feel safer, make more accurate cuts, and overall enjoy cutting a long piece of wood at your miter saw if it was on a stand like mine (see Figure 6 below), or would you rather have your miter saw on a small stand and the wood supported on either end with a pair of free-standing roller stands?

|

|

Figure 6 - Rock solid support is safer and more accurate

|

At the table saw ripping a 2-inch thick piece, 10 or 12 feet long, by 9 or 10 inches wide means I am trying to lift one end of a very heavy piece of wood, hold it tight to the fence, while feeding it through the table saw. It is a tough task. Using a roller stand on the infeed side helps some, but it also means I am usually fighting to keep the board edge against the fence (see Flaw Number 4 above). Ripping the same piece on the band saw, which I very often do, means I need to support both the infeed and outfeed sides at the same time, due to the relatively small size of the band saw table. Then I am fighting the roller alignment trying to pull the board off course on both sides of the cut.

|

Figure 7 - Getting the roller aligned perfectly perpendicular to the

direction of wood travel is nearly impossible…

|

Making a better portable work support has been a long-held desire, but it seems I always found something more critical to do with my time. Now that I have tackled designing and building a storage cabinet for underneath the extension table of my SawStop table saw, there is a chance to have that very same cabinet do double duty as a sturdy, level, safe work support.

|

Figure 8 - ...and if it is off only one or two degrees,

the roller will pull the work piece out of alignment

|

Click here

to watch the first installment of my

latest project video series

, "Under-Extension-Table Compact Table Saw Storage, Infeed, Outfeed, and Multipurpose Cabinet." That's a mouthful, so by next month we'll try to come up with a shorter name!

(Page 3 of 3)

Previous Page

1

2

3

Steven Johnson is retired from an almost 30-year career selling medical equipment and supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis (although he says home improvement projects and furniture building have been hobbies for most of his adult life). Steven can be reached directly via email at

sjohnson@downtoearthwoodworking.com

Return to the

Wood News Online

front page

|

|

|

|

|