|

|

|

|

The Down to Earth Woodworker

By Steven D. Johnson

Racine, Wisconsin

|

|

Previous Page

1

2

3

Many Roads… One Destination

Click on any picture to see a larger version.

A young just-starting-out woodworker asked me a series of questions about breaking down plywood sheets for some cabinets he intends to build. I didn't mean to but realized, after re-reading some of the emails, I sounded a bit like a politician (yikes!). The fact is, though, it was hard not to sound "evasive." It was impossible to give firm absolute answers simply because there are so many ways to accomplish the same task. This applies to many workshop activities. To some extent we utilize the tools we have and the techniques with which we are most comfortable.

A big strong person with a big

table saw

and the appropriate in-feed and

out-feed supports

could just throw sheets of plywood onto the table saw and start cutting. Those of us who are starting to grow more hair in our ears than on our heads might prefer to break sheets down into more manageable sizes before heading to the table saw. We could do that with a circular saw, a track saw, or even a jig saw… the first edge isn't as important as the last edge, and the table saw will likely leave a clean straight edge no matter what we use to initially break down the sheets.

My new friend wants to use the

Festool TS 75

and

Guide Rail

he purchased to make initial cuts, then go to the table saw. But then the question came, "How do I get absolutely square cross cuts?" My answer was again somewhat oblique, even though the intended cut should not be. "If the piece isn't too wide or too long, you can crosscut at the miter saw or on the table saw with a sled. Or you can be really, really careful and make the cut with the guide rail and track saw." I can't blame him for getting a little frustrated… he wanted straightforward absolute answers and I was talking options and variables, dancing like a politician being questioned by real journalists.

|

|

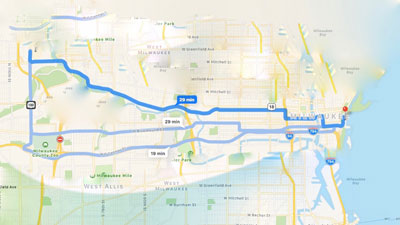

Figure 2 - Three routes among dozens between two of my favorite places

|

Both of us were getting a little exasperated until I finally tried an analogy. I described a commute to work, with three different possible routes to get there. Most days a person takes route "A," but sometimes, just to change things up, takes route "B." Every once in a while, route "C" is used because that direction takes the person by another place he or she wants to stop on the way to work (perhaps a special doughnut shop or the dry cleaners… you get the idea). All three routes will get our hypothetical person to work. The choice of route can be changed due to weather, construction, congestion, convenience, whim, or any of a dozen other reasons.

Case in point. With a lot of

projects in the Down To Earth Woodworking shop

all progressing simultaneously, as well as two major remodeling projects in my house, it is inevitable that at some point a tool will be temporarily unavailable. It might be a tricky set-up on the router table when I need to quickly round over an edge, or the dado stack is in the table saw and I need to rip a single board, which is what recently happened. The piece was entirely too narrow to rip with the

Festool TS 55

and

Guide Rail

so I drew a straight line and cut well outside the line with a jig saw. Then I used a hand plane to make the just-cut edge smooth and straight. Worked like a charm. It was a little extra work, but for just one board, hey, what the heck! I could have ripped the piece on the band saw as well, but it was a 12-foot long piece, and I would have had to move the band saw to have enough in-feed room. Now that I think about it, I could have used a little hot-melt glue and temporarily attached the thin piece to a wider piece and made the cut with the Festool Track Saw. So many ways to get the same job done… so many routes to get to the same destination.

(Page 2 of 3)

Previous Page

1

2

3

Next Page

Steven Johnson is retired from an almost 30-year career selling medical equipment and supplies, and now enjoys improving his shop, his skills, and his designs on a full time basis (although he says home improvement projects and furniture building have been hobbies for most of his adult life). Steven can be reached directly via email at

sjohnson@downtoearthwoodworking.com

Return to the

Wood News Online

front page

|

|

|

|

|